Day 1 :

Keynote Forum

Lew P Christopher

Lakehead University, Canada

Keynote: Sustainable production of bioenergy and value-added products for the growing low-cost bioresource economy

Time : 09:00-09:25

Biography:

Dr. Lew Christopher holds a Masters degree in Chemical Engineering, Ph.D. degree in Biotechnology, and has more than 20 years of industrial and academic experience. Currently he serves as Director of the Biorefining Research Institute at Lakehead University. His research mission is to add value to the emerging Bioeconomy by applying an integrated biorefinery approach to the development of renewable energy technologies. Dr. Christopher is member of the editorial board of several international biotechnology journals, advisory boards, and professional societies. He has made over 400 scientific contributions to the field of bioprocessing of lignocellulosic biomass.

Abstract:

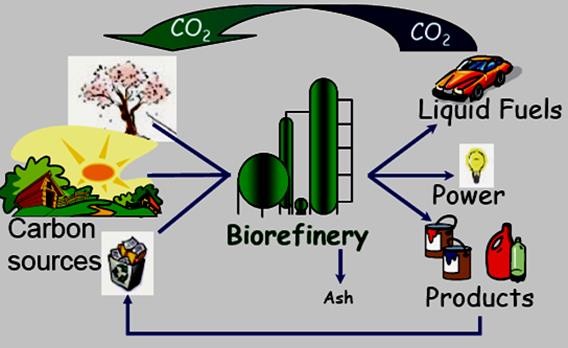

The global trend for production of bioenergy and bioproducts from renewable resources is currently steered by three important drivers: 1) diminishing reserves of readily recoverable oil and fluctuating oil prices; 2) growing food and energy needs; and 3) increasing greenhouse gas (GHG) emissions. The global production of plant biomass, over 90% of which is lignocellulose, is about 2 x 1011 tons per year, with up to 2 x 1010 tons of the primary biomass remaining potentially accessible and available for bioprocessing. Current estimates indicate that the global energy demand will continue to increase and reach 653 exajoules (EJ) in 2020) and 812 EJ in 2035. At a price of $107 per oil barrel, the cost of the lignocellulosic feedstock (US $2.6/GJ at $50/dry ton biomass) is lower than natural gas ($3.3/GJ) and crude oil ($17.2/GJ). However, at the current low oil prices, the cost of lignocellulose conversion ($20/GJ) exceeds nearly twice that of fossil fuels, which necessitates further optimization of the biomass conversion routes. Lignocellulosic biorefineries are the ultimate integrated biomass conversion facilities that are nowadays viewed as one of the major economic pillars of the emerging global Bioeconomy. However, less than 10% of thel global fuels and chemicals production is currently biobased. This is mainly due to the fact that bioproducts are not yet cost-competitive to their petroleum-based counterparts. As the biomass feedstock comprises about 50% on average of the total production costs, it has now been recognized that low-value biomass and biomass waste streams can provide a cost-effective alternative to improve the economic viability of biorefineries. Among other, this approach offers two major advantages: 1) significantly lower bienergy production costs; 2) significantly reduce waste treatment costs, carbon footprint and GHG emissions. This presentation will discuss opportunities for valorization of industrial, agricultural and municipal biomass waste and related technological challenges that we need to overcome in our transition to a low-cost bioresource economy and biobased society.

Recent Publications:

1. Christopher LP (2013) Integrated Forest Biorefineries: Challenges and Opportunities. Royal Society of Chemistry, Cambridge, UK (ISBN978-184973-321-2).

2. Christopher LP (2012) Adding value prior to pulping: Bioproducts from hemicellulose. In: Global Perspectives on Sustainable Forest Management, InTech, Chapter 14, pp. 225-246.

3. Christopher LP, Hemanathan K, Zambare VP (2014) Enzymatic biodiesel: Opportunities and challenges. Appl Energy 119: 497-520.

4. Talluri S, Raj SM, Christopher LP (2013) Consolidated bioprocessing of untreated switchgrass to hydrogen by the extreme thermophile Caldicellulosiruptor saccharolyticus DSM 8903. Bioresour Technol 139: 272-279.

5. Upadhyaya B, DeVeaux LC, Christopher LP (2014) Metabolic engineering as a tool for enhanced lactic acid production. Trends Biotechnol 32: 637–644.

Keynote Forum

Animesh Dutta

University of Guelph, Canada

Keynote: Biocarbon, biomethene, and biofertilizer from corn residue: A circular economy concept

Time : 09:25-09:50

Biography:

Animesh Dutta is a Professor and Director of Bio-renewable Innovation Lab, and Associate Director, Graduate studies with the School of Engineering at the University of Guelph. Dr Dutta is specialized in advanced energy systems and thermo-fluid science with hands-on experience in reactor design and pilot plant operation, design and performance of various tests in laboratory scale and pilot scale units, thermal design and process development. In his career, he has published over 75 peer-reviewed journal papers, 3 book chapters, and has roughly 85 conference publications and reports.

Abstract:

The three major challenges in the 21st century are food security, climate change and energy sustainability. Bioenergy is one promising renewable energy source with low net CO2 emissions and potentially sustainable if the economical, environmental and social impacts are properly managed. The development of clean and economically viable biomass conversion technologies for a domestic market is thus imperative to promote the local utilization of biomass residues in Canada. Recently Ontario Government of Canada passed the waste free Ontario, 2016 act which is the Resource Recovery and Circular Economy act (Bill 151, 2016). In the “Circular Economy act” resource recovery, and waste reduction strategy will create opportunities and markets of recovered resources. This will minimize greenhouse gas (GHG) emissions and environmental impacts in the strategy of “Waste-Free Ontario”. In this research a hybrid thermochemical and biochemical approach is proposed to produce biocoal, biomethene and biofertilizer from corn residue (CR) using the concept of circular economy. In this approach, CR is first pretreated in hydrothermal carbonization (HTC) process to produce solid biocoal. HTC process water (HTPW), a co-product of HTC processing underwent fast digestion under anaerobic conditions (AD) to produce biomethene and biofertilizer. Effects of operating conditions (process temperature and residence time) on both bio-coal and HTPW contents were studied. This process produced hybrid bioenergy of 15.71 MJ kg-1 of raw CR with an overall energy yield of 86.65%. Biocarbon produced in 240C for 30 min and 260C for 10 to 30 min were comparable to pulverised coal used in power plants, which contained HHVs of 23.01 MJkg-1 to 24.70 MJkg-1. Nutrient enriched AD digestate is useable as liquid fertilizer. Biocoal, biomethene and bio-fertilizer produced at 240C for 30 min HT process can contribute to the circular economy enrichment and reduction of greenhouse gas (GHG) emission in Ontario.

Keynote Forum

Weilan Shao

Jiangsu University, China

Keynote: Advanced molecular techniques to improve the activity and production of lignocellulases

Time : 09:50-10:15

Biography:

Weilan Shao has completed her PhD from the University of Georgia and postdoctoral studies from University of Wisconsin. She has been a distinguished professor Jiangnan University, Nanjing normal University and Jiangsu University in China since 2000. Dr. Shao and her group have discovered a series of novel lignocellulases, the key aldehyde dehydrogenase for ethanol formation, the repressor/operator system coupling glycolysis and fermentation pathways, and the regulation mechanism of thermophilic ethanol fermentation. Dr. Shao also invents new techniques for industrial enzyme production and modification.

Abstract:

Many interesting and important tests are stopped at protein preparation from a target gene, and the industrial applications of lignocellulases are hindered by the high costs of enzyme production. A gene expression system of E. coli, pHsh, was constructed to enhance the production of recombinant enzymes by using the consensus promoter of heat shock (Hsh) proteins. The target gene in pHsh is under the control of an alternative sigma factor, σ32, and its expression is induced by a temperature up-shift. The presence of pHsh increases σ32 concentration in E. coli cells, which could strengthen the transcription of heat shock chaperons. Therefore, pHsh exhibits advantages in allowing healthful growth of recombinant cells, increasing production of target protein, and decreasing inclusion body formation. Based on pHsh system and mediated by a thermostable DNA ligase, in situ error-prone PCR technique has been developed to perform directed evolution in a step of PCR amplification and plate selection. Combining the techniques of pHsh expression, site-directed mutagenesis, and directed evolution, we are able to modify genes coding for lignocellulases with desired properties, e.g. the genes encoding extremely thermostable xylanase and laccase have been improved, and enzymes can be efficiently produced for biobleaching pulp at high temperatures. These advanced techniques will enhance the biodegradation of lignocellulosic biomass for the industrial applications of bioenergy.

Keynote Forum

Rintu Banerjee

IIT Kharagpur, India

Keynote: An Overview of Biofuel Production in India: Scope and Future Goal

Time : 10:15-10:40

Biography:

Rintu Banerjee, Ex-MNRE- Chair-Professor, Indian Institute of Technology, Kharagpur has created a niche of her own in the area of Biomass Deconstruction/Biofuel Production/Enzyme Technology. In the process of her innovative development, she was granted 8 Indian, 3 International (US, Japanese and Chinese) patents. She has published more than 150 papers in peer-reviewed national/international journals, guided 27 (17 continuing) Ph.Ds, 3 MS, 71 (3 continuing) M.Techs, 50 (2 continuing) B.Techs. She is the Editorial member of many Journals. She has written 24 book chapters and authored a book on “Environmental Biotechnology” published by Oxford University Press. She is recipient of various awards/honours given by both government/non-government organizations.

Abstract:

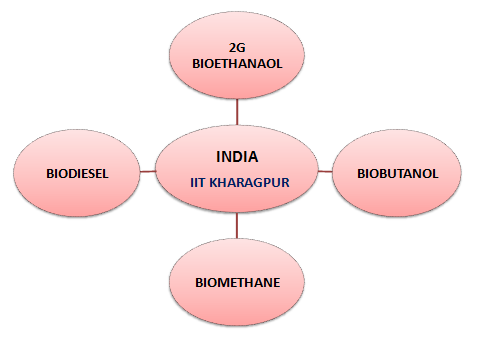

India the second most populated country after China is one of the largest emitter of green house gases (GHG). Transport sector of India accounts to 13 percent energy-related carbon-dioxide emissions. However, the ever-expanding transport sector can become more eco-friendly and sustainable by channelling the climate change agendas through cutting edge biotechnological research. The transport emissions and demand of gasoline can be reduced by adopting a sustainability approach, which includes long term goals such as increased use of public transport, higher production of biofuel, and improved vehicle efficiency. The current policy scenarios illustrates that in the next two decades India’s primary energy demand will double, from 750 Mtoe in 2011 to 1469 Mtoe in 2030. In this perspective, biofuel are emerging as the most promising alternative options to conventional fuels, as they can be produced locally, and can substitute diesel or gasoline to meet the transportation sector’s energy requirements. Specifically second generation biofuel could have positive implications for national energy security, local air quality and GHG mitigation, employment generation and rural development. The present work highlights the current status and potential of biofuel in India, identifies key challenges in achieving the country’s biofuel targets, and analyses their role in India’s long-term transport scenarios. IIT Kharagpur engaged in lignocellulosic biofuel production utilizing non-edible lignocellulosic biomass. The entire 2G biofuel production process is cost effective enzymatic venture where in-house enzymes are being produced from the new isolates from local habitat and thus, is devoid of any chemical use that makes the process eco-friendly and sustainable in nature with the integrated approach of bio-refinery having improved yield of bioethanol, biomethane and biobutanol.

Recent Publications:

- Banerjee R, Chintagunta AD, Ray S (2017) A cleaner and eco-friendly bioprocess for enhancing reducing sugar production from pineapple leaf waste. Journal of Cleaner Production http://dx.doi.org/10.1016/j.jclepro.2017.02.088.

- Avanthi A, Banerjee R (2016) A strategic laccase mediated lignin degradation of lignocellulosic feedstocks for ethanol production. Industrial Crops and Products 92, 174-185.

- Rajak RC, Banerjee R (2016) Enzyme mediated biomass pretreatment and hydrolysis: A biotechnological venture towards bioethanol production. RSC Advances, 6, 61301-61311.

- Gujjala LKS, Bandyopadhyay TK, Banerjee R (2016) Kinetic modelling of laccase mediated delignification of Lantana camara. Bioresource Technology, 212, 47-54.

- Rajak RC, Banerjee R (2015) Enzymatic delignification: An attempt for lignin degradation from lignocellulosic feedstock. RSC Advances, 5, 75281-75291.

Break: Group Photo & Coffee Break @ Foyer 10:40-11:00

- Track 9: Biofuels

Track11: Bioethanol

Track 12: Biomass Technology

Location: Spain

Session Introduction

Markus Brautsch

University of Birmingham, Germany

Title: Duel Fuel Technology in Biomass CHP-Systems

Time : 10:40-11:00

Biography:

Markus Brautsch is Full Professor for Thermodynamics, Energy Technology and Renewable Energies at the Technical University of Applied Sciences Amberg-Weiden since 1998. He is the founder of the Institute of Energy Technology and the Bavarian Center of Excellence for Combined Heat and Power Generation. In 2014 he was appointed to a Guest Professor at the Jiangsu University of Science and Technology in China. He is guest lecturer at the Renewable Energy Center in Mithradam (India) and the University of Santa Caterina (Brazil).

Abstract:

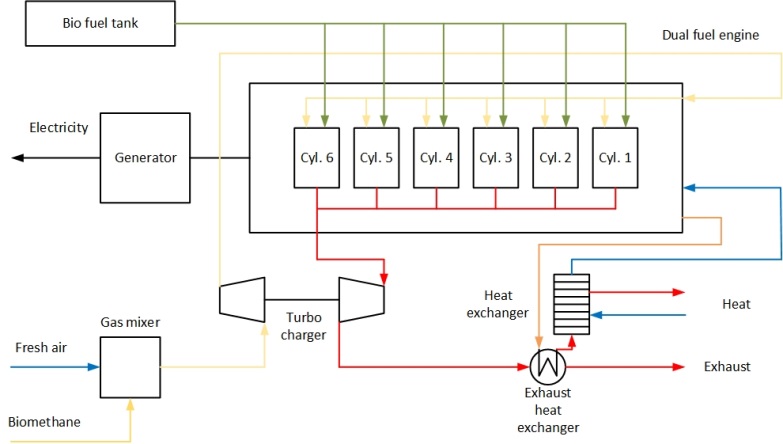

As a part of the research project “Comparison of CO2 mitigation costs of biomass CHP systems” a MAN common rail Diesel CHP system with 240 kW electrical and 230 kW thermal power was investigated in liquid fuel operation. Based on these initial measurements a dual fuel operation system with liquid and gaseous biogenous fuels was developed.

First, step the electrical efficiency, the thermal efficiency, the power coefficient and the emissions with different liquid biogenous fuels (rapeseed oil, soybean oil, biodiesel and palm oil) were investigated from part load to full load at compression rates of 19:1 and 16:1. The CHP system was driven under 100 % liquid fuel operation.

Second, biomethane was mixed with the combustion air to reduce the amount of liquid fuels to a minimum as “pilot fuel”. Beginning with 0 % (liquid fuel operation) the gas ratio was increased to its individual maximum. Investigations of the combustion behaviour by a cylinder pressure indicator system on each single cylinder attested a crucial influence of the point of the pilot fuel injection and the amount of pilot fuel. Hence, the biomethane ratio could be raised to its highest degree adapted to each different liquid biofuel.

As a result, different combinations of biomethane and biogenous liquid fuels were optimized in a highly efficient common rail Diesel CHP system. Compared to Gas-Otto CHP units, the dual fuel technology shows better electrical and thermal efficiencies as well as CO2 advantages.

Recent Publications:

- Lechner R., O´Connell N., Brautsch M.: Identifikation von Einsatzmöglichkeiten und der Zündstrahltechnologie zur Verbesserung der Anlageneffizienz und Wirtschaftlichkeit von BHKW-Anlagen mit experimentieller Überprüfung der Vorteile an einer Pilotanlage unter realen Bedingungen im Praxisbetrieb. Forschungsinitiative ZukunftBau, F 2943.Stuttgart: Fraunhofer-IRB-Verl. 2015

- Grünig G.: Zündstrahlmotoren – Effiziente Verbrennung von Biogas und Schwachgasen in Blockheizkraftwerken; 1. Auflage München; Süddeutscher Verlag onpact GmbH; 2010; ISBN 978-3-86236-008-6

- Bhaskor J. Bora, Ujjwal K. Saha: Optimisation of injection timing and compression ratio of raw biogas powered dual fuel diesel engine; Applied Thermal Engineering 92 (2016), 111-121

- Bhaskor J. Bora, Ujjwal K. Saha: Experimental evaluation of a rice bran biodiesel – biogas run dual fuel diesel engine at varying compression ratios; Renewable Energy 87 (2016), 782-790

- Debabrata Barik, S. Murugan: Experimental investigation on the behavior of a DI diesel engine fueled with raw biogas-diesel dual fuel at different injection timing; Journal of the Energy Institute 89 (2016), 373-388

Raphael Lechner

Technical University Amberg-Weiden, Germany

Title: Hydraulic Injection Characteristics of different Biofuels

Time : 11:20-11:40

Biography:

Raphael Lechner studied Environmental Engineering, Renewable Energies and Energy Efficiency at the Universities of Amberg and Kassel. He is head of R&D at the Institute of Energy Technology at the Technical University of Applied Sciences Amberg-Weiden and since 2014 director of the Bavarian Center of Excellence for Combined Heat and Power Generation.

Abstract:

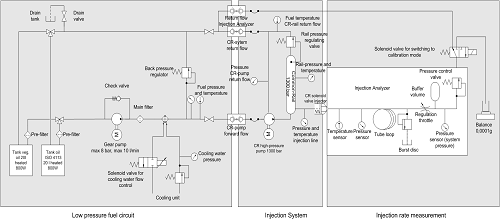

As a part of a joint research project of the Centre of Excellence for combined Heat and Power and Fraunhofer UMSICHT, the hydraulic injection characteristics of various biofuels for diesel engine operation were investigated.

The measurements were carried out using a standard configuration common-rail injection system with a high pressure pump feeding into a common rail and a solenoid injector. The system was mounted on an injection system test bench, which was developed at the Technical University of Applied Sciences Amberg-Weiden (c.f. figure). The test bench features an IAV injection analyzer, which allows direct shot-to-shot measurement of injection rate and injection quantity for multiple injections per cycle, e.g. pre, main and post injection (c.f. [1],[2]).

The different biofuels investigated were pure rape seed oil, biodiesel, and crude bio-oil obtained from biogas digestate via Thermo-Catalytic Reforming (TCR®), a process developed at Fraunhofer UMSICHT (c.f. [3],[4],[5],[6]). Calibration fluid according to ISO 4113 was used as reference fuel.

The measurements were carried out at different rail pressures and injection durations in order to obtain the injector map for the different fuels. Additionally, measurements with different pre and post injection timings were performed to determine the closest possible timing of multiple injections according to the main injection.

The resulting injector maps clearly show the pressure dependency of injection quantities. Fuels with higher viscosity generally show considerable deviations from the reference fuel at lower injection pressures, whereas the differences diminish at higher injection pressures. Analysis of multiple injections shows that there is a minimum required lag time between the injection pulses to avoid converging of the individual injections. This lag time is generally higher when using fuels with higher viscosity.

Both phenomena indicate the need for recalibrating injector mappings and timings for engine operation when utilizing biofuels with fluid characteristics deviating from the reference fuel.

Recent Publications:

- Brautsch, M.; Lechner, R.: Common-Rail-Einspritzsysteme für Pflanzenöl-BHKW, University of Applied Sciences Amberg-Weiden Research Report 2008/2009, December 2008.

- Muntean, A.B. et.al.: Impact of different in-cylinder pressures on hydraulical performances of the diesel fuel injection systems, 15th International Conference on Experimental Mechanics, Porto 22-27 July 2012.

- Neumann, J. et.al.: Upgraded biofuel from residue biomass by Thermo-Catalytic Reforming and hydrodeoxygenation. Biomass and Bioenergy 89 (2016), p. 91-97.

- Neumann, J. et.al.: Production and characterization of a new quality pyrolysis oil, char and syngas from digestate – Introducing the thermo-catalytic reforming process. Journal of Analytical and Applied Pyrolysis 113 (2015), p. 137-142.

- Neumann, J. et.al.: The conversion of anaerobic digestion waste into biofuels via a novel Thermo-Catalytic Reforming process. Waste Management 47 (2016), p. 141-148.

- Conti, R. et.al.: Thermocatalytic Reforming of Biomass Waste Streams. Energy Technology 5 (2017), p. 104-110

Alberto Carmona Bosch

Abengoa Bioenergy, Spain

Title: Market view for Bioethanol: a Global perspective

Time : 11:40-12:00

Biography:

Alberto Carmona Bosch, 45, graduated at the University of Seville (Spain) and University of Paderborn (Germany) with a Bachelor in Economics and Business Administration and an Executive MBA from Institute San Telmo (partner school of IESE). Started working in Abengoa in 1999. Professional background in financial and commercial activities and promoting and financing renewable energy projects in Europe as well as acquisitions. He has been active in the international development of Bioethanol since 2005 with activities in The Netherlands, Brazil and U.S. He has lead global trading operations the last 12 years and has held several conferences in relation with Commodity markets, Ethanol markets and Risk Management.

Abstract:

Ethanol markets are mainly a function of local supply and demand and individual blending mandates. However there are non-mandatory markets that demand ethanol without the need of government intervention and purely for the octane value of Ethanol. Global trade flows appear not only because of supply and demand of the Big Three (US, Brazil and Europe) but also for many other different demands around the world. Crude prices and sugar prices play also a very important role in the price of ethanol and therefore in the market dynamics.

Even with the major opponents lobbying, whether 1G, 1.5G or 2G Ethanol continues its steady path forward as is the unique and quickest solution for reducing Greenhouse Gas emissions and improve air quality immediately.

Review of existing regulatory matters and proposals being discussed in the main Ethanol markets.

Kasalanati Prabhakar

Shymkent, Kazakhstan

Title: Pyrolysis of Coconut Shell and its Potential as Fuel

Biography:

Prabhakar is basically a post-graduate in agriculture. He pursued doctorate in biomass conversion technologies in Indian Institute of Technology Delhi, New Delhi, India. He worked in Acharya N G Ranga Agricultural University, Hyderabad, India as Professor. He has supervised thesis work of a number of research scholars in bioenergy and has a number of research papers to his credit. He contributed to the research in biomass conversion technologies mainly in pyrolysis of agricultural wastes and forest biomass. He designed a portable kiln for manufacturing charcoal at village level. He has experience in gasification of charcoal and smokeless stoves as well. In addition, he has experience in biofuels and solar power in irrigation systems.

Abstract:

The pyrolysis of coconut shell in experimental conditions at different temperatures for varying time periods, to determine the suitable range for obtaining maximum percentage yield of charcoal was studied. Pyrolysis under field conditions has been done to compare the percentage yield efficiency of charcoal with experimental results. The efficiency of pyrolysis in experimental conditions at a temperature of 300 degree Celsius and 180 seconds’ time duration is 70%, while in field conditions the efficiency recorded is 27%. Coconut shell with a yield potential of 2 tonnes per hectare per year in India can fulfil the cooking and heating requirements of two families, with five members each, in rural areas.

David Bolonio

Universidad PoliteÌcnica de Madrid, Spain

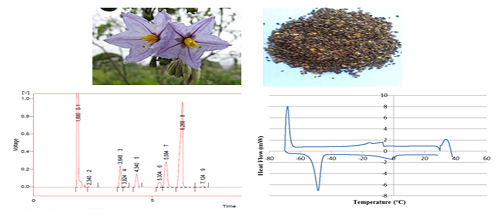

Title: Fatty acid methyl esters (FAMEs) obtained from rare seeds of Tunisia: Ibicella lutea, Peganum harmala, Smyrnium olusatrum, Onopordum nervosum and Solanum elaeagnifolium

Time : 12:00-12:15

Biography:

David Bolonio is in the third year of his PhD. He studied Mining Engineer and the Master in Environmental Research, Modeling and Risk Assessment at the Universidad Politécnica de Madrid. He has done research stays at the Faculty of Chemistry of the University of Graz and at the Joint Bioenergy Institute (Lawrence Berkeley National Laboratory). He has attended seven conferences presenting his research works and has published four papers in high impact journals.

Abstract:

The transport sector is a major energy consumer with the 27 % of the total energy used worldwide. This energy is almost completely provided by petroleum, a non-renewable resource that is concentrated in politically unstable countries and that causes global warming due to the greenhouse gas effect. Due to this situation, and the increase in the demand and the oil price, it is necessary to search for alternatives which may be used as transport fuels. One of the most viable alternatives are fatty esters, as they have similar properties to fossil fuels and they can be used as substitutes of conventional fuels without making big modifications to engines. This work aims to study the properties of fatty acid methyl esters (FAMEs) from Tunisian oils in order to assess their potential use as biofuel sources. The oils chosen for this study have been scarcely researched by other authors and are very interesting for a possible exploitation as fuels. Some of them are non-edible sources and all of them can be grown in arid places with no need of supplementary water: Ibicella lutea, Peganum harmala, Smyrnium olusatrum, Onopordum nervosum and Solanum elaeagnifolium. Their properties (cloud point, pour point cold filter plugging point, oxidation stability, cetane number, density, kinematic viscosity and heating value) have been predicted using equations that correlate the above properties with their ester profiles, measured with gas chromatography (GC-FID) and gas chromatography coupled with mass spectrometry (GC-MS), and crystallization onset temperature (COT), measured by differential scanning calorimetry (DSC). The work concludes with the comparison of the properties of the biodiesel obtained from these oils and the analysis of their possible use as biofuel sources.

Recent Publications:

- Neifar, M., Chouchane, H., Maktouf, S., Gara, J., Jaouani, A., & Cherif, A. (2016). Improved sugar yield for bioethanol production by modelling enzymatic hydrolysis of Peganum Harmala biomass through response surface methodology.

- Evergetis, E., & Haroutounian, S. A. (2014). Exploitation of apiaceae family plants as valuable renewable source of essential oils containing crops for the production of fine chemicals. Industrial Crops and Products, 54, 70-77.

- Arfaoui, M. O., Renaud, J., Ghazghazi, H., Boukhchina, S., & Mayer, P. (2014). Variation in oil content, fatty acid and phytosterols profile of Onopordum acanthium L. during seed development. Natural product research, 28(24), 2293-2300.

- Kolisis, F. N., Sotiroudis, T. G., & Sotiroudis, V. T. (2010). The potential of biodiesel production from fatty acid methyl esters of some European/Mediterranean and cosmopolitan halophyte seed oils. Journal of ASTM International, 7(3), 1-9.

- Bolonio, D., Llamas, A., Rodríguez-Fernández, J., Al-Lal, A. M., Canoira, L., Lapuerta, M., & GoÌmez, L. (2015). Estimation of cold flow performance and oxidation stability of fatty acid ethyl esters from lipids obtained from Escherichia coli. Energy & Fuels, 29(4), 2493-2502.

- Lapuerta, M., Rodríguez-Fernández, J., & Armas, O. (2010). Correlation for the estimation of the density of fatty acid esters fuels and its implications. A proposed biodiesel cetane index. Chemistry and physics of lipids, 163(7), 720-727.

Avanthi Althuri

Indian Institute of Technology - Kharagpur, India

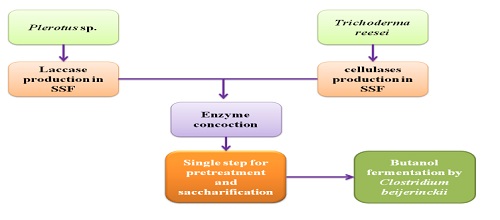

Title: Simultaneous delignification and saccharification of mixed lignocellulosics for improved ethanol production in a single bioreactor: An eco-friendly enzymatic venture

Biography:

Althuri Avanthi, has graduated M.Tech under the guidance of Prof. Rintu Banerjee, IIT Kharagpur. Since 2012 she is pursuing PhD under same Professor at IIT Kharagpur. She is availing DBT scholarship since 2012 and had received GATE 2010-12 fellowship. Her current doctoral dissertation topic deals with biomass and biofuels with special emphasis on bioethanol production from holocellulosic stream of mixed lignocellulosic biomass.

Abstract:

Lignocellulosic ethanol is the energy of the future that has the potential to replace petro-fuels when driven by a simple and competent biomass processing technology[1,2]. In the midst of alarming environmental consequences of industrialization and excessive fossil fuel combustion, it is obligatory to seek for a greener and benign approach for 2G ethanol production[3]. The present study is one such attempt that deals with enzymatic processing of carbon neutral lignocellulosics. For this a blend of nonedible lignocellulosics namely, Ricinus communis, Saccharum officinarum tops and Saccharum spontaneum was taken as a substrate, since collection of a single type of biomass to feed a refinery is time consuming, laborious and cost intensive. Whereas mixed feedstocks are readily available, sustainable and moreover are tailor made to fit in the best biochemical composition[4]. Biomass blend considered showed high carbon% and energy density[5].

The present study involved simultaneous biomass pretreatment and hydrolysis using a cocktail of enzymes consisting of ligninolytic laccase from Pleurotus djamor and a complete holocellulolytic system from Trichoderma reseei RUT C30 consisting of endo-glucanase, exo-glucanase, β-glucosidase and xylanase for hydrolysis. This enzyme based simultaneous pretreatment-saccharification (SPS) of biomass was found to yield higher reducing sugars (633 mg/g) than sequential pretreatment-saccharification (SePS, 600 mg/g), chemical pretreatment-saccharification (CPS, 367 mg/g) and chemical pretreatment-enzymatic saccharification (CPES, 526 mg/g). Ethanol concentration from co-fermentation of sugars was observed to be 7.1% (v/v). Further improved ethanol concentration up to 7.65% (v/v) was observed when biomass was subjected to SPS for 2h and followed by co-fermentation in same vessel. Statistical model was used to evaluate and validate the performance of this partially consolidated bioprocessing (PCBP). Biomass to ethanol conversion was 26.5% (g/g) with 60.35 g/L ethanol. The adopted process has meagre allied waste streams and thus aids in safeguarding the environment for future generations.

Sanjeev Kumar

Indian Institute of Technology, Kharagpur, India

Title: A challenging attempt towards utilization of non-edible lignocellulosics for cost-effective biobutanol production

Time : 12:15-12:30

Biography:

Sanjeev Kumar, PhD student is working under the esteemed guidance of Prof. Rintu Banerjee at Advanced Technology Development Center, Indian Institute of Technology, Kharagpur, India. He is working on second generation biobutanol production using Clostridium beijerinckii.

Abstract:

Global raise in the living standards of the society throughout the world has created a huge demand for transportation fuel. Conventionally energy demand used to be met through the use of fossil fuels but due to environmental concerns, sustainable sources of fuels are being researched upon nowadays. In this venture, biofuels have gained immense popularity since they are carbon neutral and has the potential to fulfill the demand1. Nowadays pretreatment and saccharification of lignocellulosics is performed sequentially in order to obtain fermentable sugar for biofuels production2,3. In the present study, pretreatment and saccharification was investigated concomitantly to obtain reducing sugars from bamboo using laccase and cellulases extracted from solid state fermentation of Pleurotus sp. and Trichoderma reesei respectively. One of the main advantages of this process is the overall time reduction since pretreatment and saccharification is conducted simultaneously. Laccase assists in increasing cell wall permeability by degrading the lignin and thus facilitated the diffusion of enzymes into the cell wall to cause hydrolysis of holocellulose for the production of fermentable sugars. Process parameters governing the system viz., temperature, incubation time, pH, cellulase: laccase ratio in the enzyme cocktail and solid loading were optimized using response surface methodology thus producing a maximum reducing sugar content of 75.45 g/L. HPLC analysis revealed that broth has mixtures of glucose (36.89%), pentoses (24.29%) and cellobiose (38.81%). The potential of these sugars was analyzed using Clostridium beijerinckii by converting the sugar rich broth into butanol4. Clostridia have the capability to utilize C6, C5 and disaccharide sugars

Recent Publications:

- Procentese, A., Raganati, F., Olivieri, G., Russo, M.E., Marzocchella, A., 2017. Pre-treatment and enzymatic hydrolysis of lettuce residues as feedstock for bio-butanol production. Biomass Bioener. 96, 172–179.

- Ma, K., Ruan, Z., 2015. Production of a lignocellulolytic enzyme system for simultaneous bio-delignification and saccharification of corn stover employing co-culture of fungi. Bioresour. Technol. 175, 586–593.

- Dhiman, S.S., Haw, J., Kalyani, D., Kalia, V.C., Kang, Y.C., Lee, J., 2015. Simultaneous pretreatment and saccharification: green technology for enhanced sugar yields from biomass using a fungal consortium. Bioresour. Technol. 179, 50–57.

- Kumar, S., Gujjala, L.K.S., Banerjee, R., 2017. Simultaneous pretreatment and saccharification of bamboo for biobutanol production. Ind. Crops Prod. (Accepted)

- Al-Shorgani, N.K.N., Isa, M.H.M., Yusoff, W.M.W., Kalil, M.S., Hamid, A.A., 2016. Isolation of a Clostridium acetobutylicum strain and characterization of its fermentation performance on agricultural wastes. Renew. Energy, 86, 459–465.

- Track 1: Biomass feed stocks for renewable energy generation

Track 2: Biomass

Track 3: Bioenergy Conversion

Location: Spain

Session Introduction

Richard Sayre

Los Alamos National Laboratory, USA

Title: Improving Photosynthetic Efficiency and Biomass Yield in Plants and Algae

Time : 14:30-14:50

Biography:

Richard Sayre is a Senior Research Scientist at Los Alamos National Laboratory (LANL) and the New Mexico Consortium (NMC). Dr. Sayre’s research interests include; enhancing photosynthetic efficiency, algal and plant biotechnology, and nutritional biofortification of crop plants. Dr. Sayre has directed several large research consortia including: 1) Phase I of the BioCassava Plus Program funded by the Bill and Melinda Gates Foundation. 2) Center for Advanced Biofuel Systems, a Dept. of Energy (DOE) Energy Frontier Research Center focusing on generating advanced biofuels from algae and plants. 3) Scientific Director of the National Alliance for Advanced Biofuels, and Bioproducts, the largest DOE-sponsored algal biofuels consortium funded to date; and 4) Director of the PACE (Producing Algae for Energy and Coproducts) targeted algal biomass and bioproducts program.

Abstract:

One of the more environmentally sustainable ways to produce high energy density (oils) liquid transportation fuels is photosynthetic reduction of carbon dioxide into carbohydrates and hydrocarbons and their subsequent conversion into fuels. Photosynthetic carbon capture from the atmosphere combined with bioenergy production (combustion) and subsequent carbon capture and sequestration (BECCS) has also been proposed by the recent Intergovernmental Panel on Climate Change Report as the most effective and economical way to remediate atmospheric greenhouse gasses. To maximize carbon capture efficiency and energy-return-on-investment, we must develop cropping systems that have the greatest aerial biomass yields with the lowest inputs. All photosynthetic organisms, however, convert only a fraction (< 5%) of the solar energy they capture into harvestable chemical energy (reduced carbon or biomass). To increase aerial carbon capture rates and biomass productivity it will be necessary to increase photosynthetic efficiency in plants and algae. We will discuss metabolic engineering strategies to improve photosynthetic efficiency and biomass productivity in algal and plant systems, often borrowing metabolic strategies from one photosynthetic system to transfer into another. These strategies include optimization of photosynthetic light-harvesting antenna size and the introduction of algal inorganic carbon concentrating systems into plants to increase carbon fixation efficiency and biomass yields. To date, these strategies have resulted into up to two-fold increases in biomass productivity in algae and crop yields in outdoor field trials.

References:

- Olivares J, et al. (2016) Review of the algal biology program within the National Alliance for Advanced Biofuels and Bioproducts. Algal Res. DOI: 10.1016/j.algal.2016.06.002.

- Kumar A, Perrine Z, Stroff C, Postier BL, Coury DA, Sayre RT and Allnutt FCT (2016) Molecular Tools for Bioengineering Eukaryotic Microalgae. Curr. Biotechnol. 5:93-108.

- Negi S, Barry AN, Friedland N, Sudasinghe N, Subramanian S, Pieris S, Holguin FO, Dungan B, Schaub T and Sayre RT (2015) Impact of nitrogen limitation on biomass, photosynthesis, and lipid accumulation in Chlorella sorokiniana. J. Appl. Phycol. DOI 10.1007/s10811-015-0652-z.

- Subramanian S, Barry A, Pieris S and Sayre RT (2013) Comparative energetics and kinetics of autotrophic lipid and starch metabolism in chlorophytic microalgae: Implications for biomass and biofuel production. Biotechnol. Biofuels 6: 150-162.

- Perrine Z, Negi S and Sayre, RT (2012) Optimization of photosynthetic light energy utilization by microalgae. Algal Res. 1:134-142.

- Blankenship RE et al., (2011) What is the solar energy conversion efficiency of natural photosynthesis compared to photovoltaic cells? Science 332:805-809.

Ralph-Uwe Dietrich

German Aerospace Center, Germany

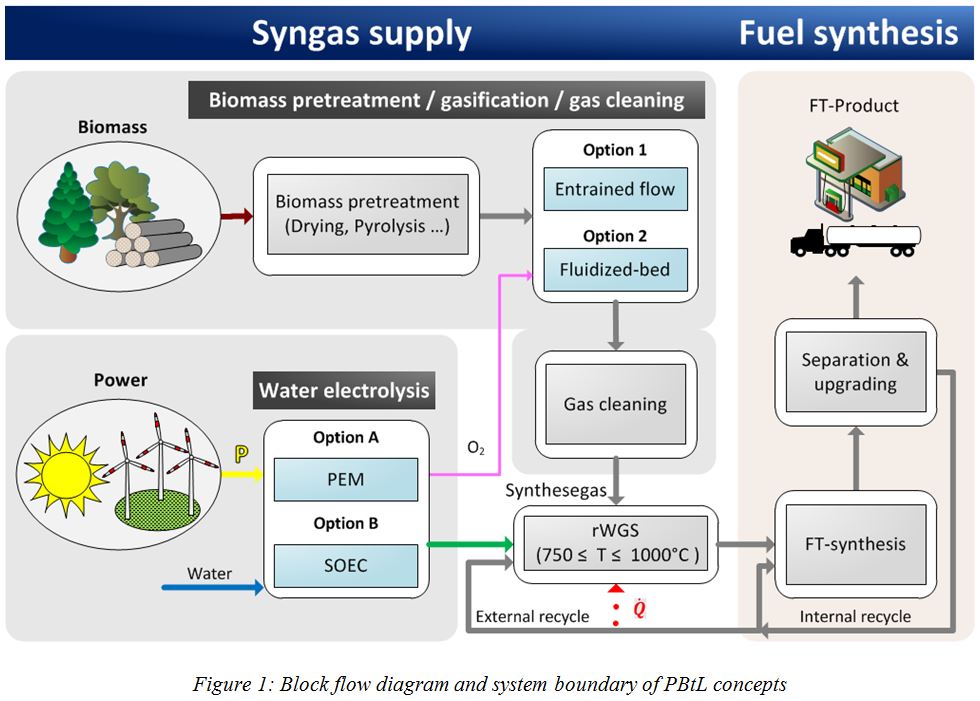

Title: Alternative fuels from Biomass and Power (PBtL) – A case study on process options, technical potentials, fuel costs and ecological performance

Time : 14:50-15:10

Biography:

Ralph-Uwe Dietrich leads the research area Alternative Fuels at the Institute of Engineering Thermodynamics at the German Aerospace Center (DLR) in Stuttgart. He is responsible for the research group on techno economic and ecologic evaluation of alternative fuels for aviation and global transport. He received his PhD in Engineering at the Technical University Clausthal in 2013 as a Scientific coworker at the Clausthaler Umwelttechnik Institute (CUTEC-Institut GmbH). Before that, he got 15 years of project manager experience at different enterprises (SME and Fortune 500) of the process and automation industry.

Abstract:

Greenhouse gas emissions in the transport sector shall be reduced to reach globally agreed COP21 goals. One option is to replace fossil based fuels with bio-based alternatives. The technical potential of biofuels made from energy crops (1st generation), biomass and waste wood (2nd generation) typically suffer from the limited technical potential of biomass resources in central Europe. Biofuel output can significantly be increased in the Power&Biomass-to-Liquid (PBtL) concept utilizing renewable electricity in modified BtL plants. The case study presents detailed results on promising process configurations of Fischer-Tropsch PBtL concepts based on different gasifiers and electrolyzers in terms of fuel production potentials, fuel costs and CO2 footprint.

Results from the study indicate that the biomass specific fuel output can be quadrupled when utilizing green electricity for hydrogen generation in the PBtL process. The increased fuel output results in lower fuel production costs due to the effects of the economy of scale. Fuel production costs below 1.3 €/l were estimated for a large PBtL plant (225 kt/year) assuming an electricity price of 31.4 €/MWh (average EEX-Phelix index of the year 2015). The exergy analysis reveals that the electrolysis and the gasification processes are characterized by the most significant thermodynamic optimization potentials. The PBtL concept is characterized by a lower CO2 footprint, as high carbon conversion rates close to 100 % can be achieved by using oxy-fuel technology and recycling the entire CO2 within the system. Hence, largest CO2 emissions arise from harvesting and transportation of the biomass feedstock.

Recent Publications:

- Albrecht, F, König, D, Baucks, N, Dietrich, R.-U. (2017) A standardized methodology for the techno-economic evaluation of alternative fuels – A case study. Fuel – The Science and Technology of Fuel and Energy, 194:511-526.

- Albrecht, F, Zhang, J, Dietrich, R.-U. (2016) Process design and economic assessment of converting CO2 to liquid fuels. ACI's 7th Carbon Dioxide Utilisation Summit 2016, 19.-20. Okt. 2016, Lyon, France.

- Albrecht, F, Dietrich, R.-U., König, D, Seitz, A, Thess, A (2016) Techno-Economic Assessment of the Production of Synthetic Jet Fuel from Carbon Sources and Renewable Hydrogen. GREENER AVIATION 2016, 11.-13. Oct. 2016, Brussels, Belgium

- Albrecht, F, König, D, Dietrich, R.-U. (2016) The potential of using power-to-liquid plants for power storage purposes. In: 2016 13th International Conference on the European Energy Market (EEM), S03_10163. IEEE Xplore Digital Library

- König, D, Freiberg, M Dietrich, R.-U. Wörner, A (2015) Techno-economic study of the storage of fluctuating renewable energy in liquid hydrocarbons. Fuel – The Science and Technology of Fuel and Energy, 159:289-297

Souman Rudra

University of Agder, Norway

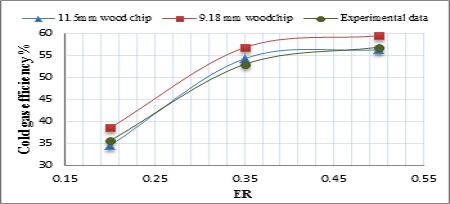

Title: Effects of variable feedstock particle size on Birchwood gasification: A CFD approach

Time : 15:10-15:30

Biography:

Souman Rudra is currently working at the University of Agder, Norway as an associate professor since 2013. He conducts research and teaching within renewable energy technology - related to biomass conversion process and thermal energy systems and analysis of energy conversion systems in general. He has his expertise in design, modeling, and simulation of the different energy system specially bio-energy system. Several articles have been published in this area. Energy and exergy analysis, LCA analysis have also done for several of his design energy systems. Based on those analyses, he has proposed a quad-generation model for producing power, heat, cooling and SNG (synthesized natural gas).

Abstract:

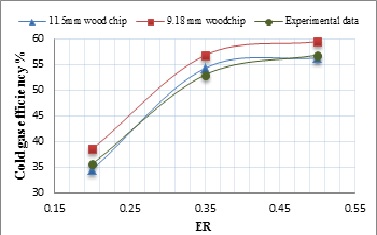

Gasification is a complex process and determining gasification characteristics experimentally is a time-consuming process. Using CFD models to predict and examine about gasification characteristics, in the various scenario can be time saving and safe. This paper primarily discusses the results of a CFD model, which simulates gasification characteristics of Birchwood. During the work, a variation of producer gas yield, syngas composition and cold gas efficiency of the syngas were investigated with a variable biomass particle size. A 3D CFD model of a fixed bed downdraft gasifier has been developed. Euler –Euler approach has been used to model the gas phase reactions while Lagrangian approach has been used to model the solid- gas reactions. For the simulations, biomass (Birchwood) particles with two different diameter sizes were used. They were 11.5mm and 9.18 mm. In this work, gasification parameters were examined within the equivalence ratio (ER) range from 0.2 to 0.5. The simulated results were validated using the actual fixed bed downdraft gasifier available at UIA, Norway. CO, CO2, CH4 and H2 mass fractions of the syngas were measured along with the calculated values of syngas yield and cold gas efficiency (CGE). With the 9.18mm diameter birchwood particle, CGE has shown an average maximum value of 59.4 % at the ER value of 0.5, which is a 4% improvement over the 11.5mm diameter biomass particle. In addition, Syngas yield has also shown an average maximum value of 2.8 Nm3/h with the 9.18 mm wood particle, which is an improvement of 0.1 Nm3/h over the 11.5 mm biomass particle.

Recent Publications:

- Prabir Basu. (2010). Biomass Gasification and pyrolysis Practical Design and Theory. ELSEVIER. (ISBN- 0080961622).

- Pratik N. Sheth, Babu BV. (2009) Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresource Technology 100:3127–3133.

- Keran D. Patel, Shah NK, Patel RN. (2013) CFD Analysis of Spatial Distribution of Various Parameters in Downdraft Gasifier. Procedia Engineering 51: 764-769.

- Gerun L, Paraschiv M, Vijeu R, Bellettre J, Tazerout M, Gøbel B, Henriksen U. (2008) Numerical investigation of the partial oxidation in a two-stage downdraft gasifier”, Fuel 87:1383

- Sarker S, Nielsen HK (2015) Preliminary fixed-bed downdraft gasification of birch woodchips. International journal of environmental science 12: 2119

- Souman Rudra, Lasse Rosendahl, Morten B. Blarke. (2015) Process analysis of a biomass-based quad-generation plant for combined power, heat, cooling, and synthetic natural gas production. Energy Conversion and Management 106: 1276–1285

Xiaolei Zhang

Queen’s University Belfast, UK

Title: Theoretical elucidation of the molecular behaviour of levoglucosan during biomass pyrolysis

Time : 15:30-15:50

Biography:

Xiaolei Zhang is a Lecturer at the Queen’s University Belfast (QUB), UK since January 2015. She received a PhD in May 2013 from the Royal Institute of Technology (KTH), Sweden on the topic of quantum mechanics investigation of bioenergy systems and she has worked as a researcher at University of Alberta, Canada on process modelling of bioenergy system for 14 months. Rich international research achievements of Dr Zhang are reflected by the authored 20 peer-reviewed publications in leading international journals in the area of Energy, with over 200 citations and an H-index of 9 on Scopus; together with the delivery of 22 invited talks, lectures, and other conference contributions.

Abstract:

The bio-fuels and bio-chemicals derived from lignocellulosic biomass are popularly referred to as second-generation bio-fuels or bio-chemicals. As a valuable chemical material, levoglucosan is one important primary product during cellulose pyrolysis either as an intermediate or as a product. The fundamental investigation on the mechanism and kinetic modelling of the production of levoglucosan from lignocellulosic biomass has been carried out. Three available mechanisms for levoglucosan formation have been studied theoretically by performing density functional theory based calculations. Specifically, the molecular behaviour of levoglucosan has elucidated by revealing 14 reaction pathways, 26 elemental reaction steps, and the involved around 60 compounds act as intermediates, transition states, or products. By comparing with the activation energy obtained from the experimental results, it was concluded that levoglucosan chain-end mechanism fits better with the experimental data for the formation of levoglucosan. The variational transition state rate constants for every elementary reaction and every pathway were calculated. The first-order Arrhenius expressions for these elementary reactions and pathways were suggested. Furthermore, this research provides techno-economic assessment of the available routes for the production of levoglucosan and its derived products, and the paper will be concluded by identifying key challenges and future trends for second-generation bio-chemicals. It also confirms that Quantum Mechanics based simulation can reveal fundamental phenomena, which are difficult to be explored from traditional experimental techniques, and can be used to guide the experimental design and industrial application.

Recent Publications:

- Zhang, X. (2016), Essential scientific mapping of the value chain of thermochemical converted second-generation bio-fuels. Green Chemistry. 18, 5086-5117

- Zhang, X., Kumar, A., Oestreich, D., Arnold, U., and Sauer, J. (2016). An optimization process design for woody biomass gasification with further upgrading into oxymethylene ethers. Biomass and Bioenergy. 90, 7–14.

- Zhang, X., Yang, W. and Blasiak, W. (2013). Kinetics Study on Thermal Dissociation of Levoglucosan during Cellulose Pyrolysis. Fuel, 109, 476–483.

- Zhang, X., Yang, W. and Blasiak, W. (2013). Levoglucosan Formation Mechanisms during Cellulose Pyrolysis. Journal of Analytical and Applied Pyrolysis, 104, 19–27.

- Zhang, X., Yang, W. and Blasiak, W. (2012). Kinetics of levoglucosan and formaldehyde formation during cellulose pyrolysis process. Fuel, 96(0), 383–391.

Khalid FARES

Cadi Ayyad University-Marrakech, Morocco

Title: Quality of organic amendment obtained from organic waste fraction in old landfill

Time : 15:50-16:10

Biography:

Khalid Fares is Professor Teacher Researcher at Cadi Ayyad University (Department of Biology), Marrakech, Morocco. He is the Head of Biochemistry and Biotechnology of Plants Unit, President of the “Federation of African Societies of Biochemistry and Molecular Biology” and Former President of the “Moroccan Society of Biochemistry and Molecular Biology. Pr FARES is member of Moroccan Society of Biosafety as well as many professional bodies. He is also Reviewer for European Journal of Agronomy, Carbohydrate Research, Annals of Applied Biology, Journal of Agricultural and Food Chemistry and Acta Agriculturae Scandinavica. His research in the field of Food Science and Biochemistry as well as the valorization of waste was published in several journals and communicated in many international congresses. Pr FARES was the organizer of many international meeting and congresses.

Abstract:

18 000 tons of solid household wastes are produced daily in Morocco and joined generally the dump sites which reach the optimal capacity and needs therefore to be closed through rehabilitation programme. Morocco has recently undertaken a vast controlled landfill construction program and rehabilitation of old dumps. This rehabilitation is based mainly on the land filling of all wastes and construction of green spaces without any recycling or valorization of the organic part of these wastes which may constitutes a big proportion. The present work aims to determine the physicochemical and microbiological characteristics of organic substrates in the old landfill in order to use it as an organic amendment. Three samples of 100 kg each were taken from the landfill of Sidi Bennour, sieved later and the organic substrates fraction (OSF) was an analyzed chemically and microbiologically. The OSF represents 65 % in weight. This OSF was stable and hygienic especially when sugar beet lime sludge (SBLS) is added: the pH value was reduced to 8.4, the C/N ratio to 12 and no microorganism pathogen was detected. The concentrations of heavy metals were lower than the limit values ​​recommended. The germination test using aqueous extracts of the OSF showed no phytotoxicity for all plant tested. Tests on radish crop showed the lack of any toxicity and gave a good production yield. The addition of sugar beet lime sludge to the OSF and the reuse of this substrate as organic amendment could be considered as sustainable solution for the rehabilitation of the old landfill.

Santosh Sankh

Reliance Technology Group, Reliance Industries, India

Title: Alkaline pretreatment and saccharification of woody biomass: Castor Stalk

Time : 16:30-16:50

Biography:

Santosh kumar Sankh is working as senior scientist at Reliance Industries, Mumbai. He is having experience in Biofuels, biomass deconstruction research.

Abstract:

Efficient pretreatment of lignocellulosic biomass to sugars is currently needed for viable biofuel production technology. This study investigates the efficiency of alkaline pretreatment for the saccharification of woddy biomass, castor stalk. Alkaline pretreatment by using sodium hydroxide (NaOH) is capable of maintaining the highest cellulose recovery and enzymatic hydrolysis. The optimized conditions of NaOH pretreatment includes biomass load 8 % (w/v), NaOH concentration 1% (w/v), pretreatment temperature 121°C and pretreatment time 15 min. The enzymatic hydrolysis using 50 FPU of enzyme at a biomass load of 5 % (w/v) gave a hydrolysis of 46.78 % in 24 h.

Sonia Shilpi

University of Newcastle, Australia

Title: Methane production through anaerobic digestion of various energy crops irrigated with wastewaters

Time : 16:50-17:05

Biography:

Sonia Shilpi is a PhD student of University of Newcastle, NSW, Australia. She has been working on ‘Wastewater driven biomass production for energy generation’ as of her Ph.D. Program. She has completed a set of exciting experiments including “Methane production through anaerobic digestion of various energy crops irrigated with wastewaters”. She has contributed to several publications and conference presentations from her research work.

Abstract:

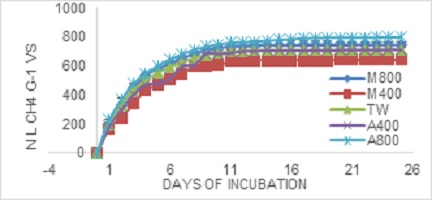

It is essential to develop sustainable energy supply systems that aim to consolidate the energy demand from renewable sources and also mitigate the emission of greenhouse gases. Biogas production is a key technology for the sustainable use of biomass as renewable energy source. High energy yields per hectare can be achieved through biogas production by using a wide range of energy crops. Maize, sunflower and Sudan grass are the most commonly used energy crops. The field experiment covered five different types of energy crops grown using two types of wastewaters viz. Abattoir (AWW) and municipal wastewater (MWW) at two different irrigation rates (400mm and 800mm) and tap water (TW). Dry biomass yield (DBY) was assessed from a field plot experiment at St. Kilda, South Australia. Total solids (TS) and volatile solids (VS) were determined on fresh biomass samples. DBY data obtained from the field trial (all five crops) increased with increasing wastewater irrigation. The plots irrigated with AWW 400 and 800 mm showed significantly higher yield than the MWW (400 and 800 mm) and TW (800mm) irrigated plots. The amount of biogas production was monitored every day and expressed as norm litre per kg of volatile solids (Nl kg-1 VS). Anaerobic digester was used to determine a reference methane yield for finely ground substrates under optimal conditions. Inoculum was obtained from a bolivar plant, Salisbury city council. Substrate/inoculum ratio based on volatile solid (VS) basis was used in all batch experiments, performed in 500 ml bottles (working volume 400 ml) in triplicate, incubated on a shaking water bath (70 rounds minute-1 (rpm)) at 37±1°C, and continued until methane production became negligible (<5 ml CH4 d-1). The methane yield per hectare was calculated by multiplication of the biomass yield and the specific methane yield. To be able to run biogas plants economically the methane yield from energy crops needs to be known. The present data show that the methane yield of energy crops depends on their nutrient composition. Maize (A800) exhibited the highest value in terms of potential methane yield (798.23 Nml CH4 g−1 VS).

Recent Publications:

- Sonia Shilpi, Balaji Seshadri, Nanthi S Bolan and Ravi Naidu. (2015). Phytotoxicity of wastewater irrigation in solution, sand and soil medium. "CRC CARE-2015. ‘Clean-up Conference”.

- S. Shilpi, M. Nuruzzaman, Fahmina Akter, M.N. Islam and G.N.C. Sutradhar. 2014. Response of Nitrogen and Sulfur on the Oil content and Nutrient status of Soil. International Journal of Bio-resource and Stress Management. 5(1):041-046.

- A. Husna, M. A. Maih, S. Begum, S. Z. Shilpi and M. R. Islam. 2014. Genetic Variability, Correlation And Path Co-Efficient Analysis Based On Vegetative Characters In Bottle Gourd (Lagenaria Siceraria L.). Advance in Agriculture and Biology. 2 (1): 8-12.

- F. Akhter, M. N. Islam, A.T.M. Shamsuddoha, S. Islam and S. Shilpi. 2013. Response of Phosphorus and Sulphur on the Growth and Yield of Soybean. International Journal of Bio- resource and Stress Management. 4(4):556-561.

- S. Shilpi, M.N.Islam, G.N.C.Sutradhar, A.Husna and F. Akhter. 2012. Effect of Nitrogen and Sulfur on the Growth and Yield of Sesame. International Journal of Bio-resource and Stress Management. 3(2): 177-182.Harper C (2009) The neuropathology of alcohol-related braindamage. Alcohol Alcohol 44:136-140.

Bobbo Nfor Tansi

BTU Cottbus, Germany

Title: Prospects and Barriers for the Sustainable Use of Second Generation Biomass from the Palm Oil Industry

Time : 17:05-17:20

Biography:

Bobbo Nfor Tansi is a PhD student at the Brandenburg Technical University Cottbus Germany. He is currently researching on “Analyzing the calorific and sustainability potential of Cameroonian palm oil residues for co firing in power plants. As a PhD student he has been assisting as a student lecturer at his university, offering courses in energy security and sustainability. Mr. Tansi has since May 2016, been teaching courses in wind energy at the faculty of engineering and technology of the university of Buea Cameroon as a visiting lecturer, He studied Geology and environmental sciences and Environmental Engineering at the University of Buea Cameroon and the Brandenburg Technical university Cottbus Germany respectively. Passionate about energy, his move towards renewable energy and energy generation has been a natural fit. In his free time he loves computer programming, swimming, bicycle riding, playing table, soccer, acting and board games such as chess and scrabble.

Abstract:

As of October 2014, 258.9 million hectares of agricultural land was being used for oilseed production. 5.5%, approximately 14.2 million hectares constituted land used for palm oil cultivation. With an estimated annual global production of 58.72 million tons in 2016, Palm oil has become the most important vegetable oil globally, greatly exceeding soybean, rapeseed and sunflower. It is the most efficient oilseed crop in the world, capable of producing up to ten times more oil than other leading oilseed crops per hectare. Annually, a hectare of mature palms could produce between 18 to 30 metric tons of fresh fruit bunches (FFB), 70-75% of which ends up as by-products or waste. Main by-products from the palm oil industry that could be used for their energetic values include the Palm Kernel shells, Empty fruit bunches, Palm oil Fiber, Oil palm trunks, Oil palm fronds and the Palm oil Mill Effluent (POME). On average a hectare of palm oil produces 15.8 tons of Palm kernel shells, empty fruit bunches, Palm oil Fibers and Oil palm fronds annually. Whereas at the end of it’s economic life span a hectare of palm oil is capable of producing an estimated 82.32 tons of dry biomass including Oil palm trunks. Residues from the palm oil plantation have a net calorific value in the range of 15MJ/kg to 22MJ/kg, comparable to brown coal (Lignite) and bituminous coal with net heating values in the ranges of 10-19MJ/kg and 15-24MJ/kg respectively. Greenhouse gas emission estimates from the production of 1kg of palm oil ranges from 0.02 to 8.32kg CO2 equivalent, with land use change and fertilizer input being the most contributors to its emission potential. The open incineration of most of these residues as a waste management process not only leads to an increase in the emissions from the sector, but also the energy from these residues is lost. Unfortunately, bioenergy still constitutes as low as 10% (50EJ) of the total primary energy supply as of 2017. With the main challenges facing the development of bioenergy being low oil prices, food security and policy uncertainty, second-generation biomass is undoubtedly the silver bullet solution to accelerate bioenergy access to the total energy mix in the near future.

Recent Publications:

- Bobbo Nfor Tansi (2012) An Assessment of Cameroons Wind and Solar Energy Potential: A Guide for a Sustainable Economic Development. Diplomica Verlag. 120p

- Track 7: Biogas

Track 10: Bioenergy Applications

Session Introduction

Jana Zabranska

University of Chemistry and Technology, Czech Republic

Title: Bioconversion of carbon dioxide in biogas to methane

Time : 11:00-11:20

Biography:

Jana Zabranska is a member of the academic staff of the Department of Water Technology and Environmental Engineering in the Faculty of Technology of Environment Protection, University of Chemistry and Technology Prague. She is engaged in the field of anaerobic digestion, degradability and methane yield from different substrates. Currently she is involved in the research of biogas production from agroindustrial wastes and biological removal of hydrogensulfide from biogas. She is a supervisor of Master and Doctor Degree students and has lectures on subjects "Anaerobic technology in environmental protection" and "Technology of biogas and biohydrogen production". She is authored and co-authored 273 scientific papers, 3 technological patents, 6 textbooks and 2 monographs. Prof. Zábranská is a member of International Water Association, Specialist group of Anaerobic Digestion, Sludge Management, a member of Czech Biogas Association, Czech Water Association, member of the Committee of the Czech Biotechnology Society.

Abstract:

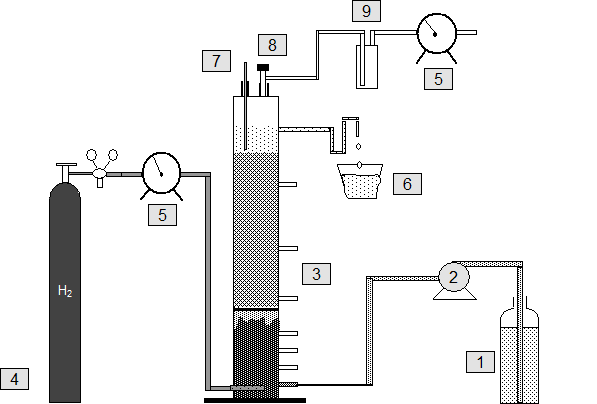

Biogas produced from organic wastes contains energetically usable methane and unavoidable content of carbon dioxide. The exploitation of whole biogas energy is locally limited and utilization of natural gas transport system requires CO2 removal or conversion to methane. Chemical methods of upgrading biogas to biomethane have disadvantage in demand of high pressure and temperature. Biological conversion of CO2 and hydrogen to methane is well known reaction and is carried out by hydrogenotrophic methanogenic bacteria. Reducing equivalents to biotransformation of carbon dioxide from biogas or other resources to biomethane can be supplied by external hydrogen. The rapidly developing renewable energy carriers include electricity from wind and solar energy. Discontinuous electricity production combined with fluctuating utilization cause serious storage problems that can be solved by power-to-gas strategy representing production of storable hydrogen via electrolysis of water. Possibility of subsequent repowering of energy of hydrogen to the easily utilizable and transportable form is biological conversion with CO2 to biomethane. The aim of our project is to find the optimal conditions of the technology of biological reduction of CO2 with H2 in terms of process parameters and device type. Biomethanization of CO2 can be applied directly to anaerobic digesters being fed with organic substrates, or in external bioreactors. Experiments started with hybrid anaerobic reactors (upflow sludge bed reactor with packed bed in the upper part) fed with distillery slops as organic substrate and gaseous hydrogen was introduced to the bottom of reactor. The major bottleneck in the process is gas-liquid mass transfer of H2 and the method of effective input of hydrogen into the system have to be optimized. The possibilities of an implementation of the technology to biogas plants will be suggested based on results of the project.

Recent Publications:

- Angelidaki I., G. Luo, and P. Kougias (2015). "Simultaneous hydrogen utilization and biogas upgrading by anaerobic microorganisms." Proceedings of 14th World Congress of Anaerobic Digestion, Viña del Mar, Chile, 15-18.11.2015, 2. biogas upgrading

- Díaz I., N. A., C. Pérez and F. Fdz-Polanco (2015). "Application of membrane modules to improve mass transfer for the chemoautotrophic biogas upgrading." Proceedings of 14th World Congress of Anaerobic Digestion, Viña del Mar, Chile, 15-18.11.2015.

- Gahleitner, G. (2013). "Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications." International Journal of Hydrogen Energy 38(5): 2039-2061.

- Luo, G. and I. Angelidaki (2013). "Co-digestion of manure and whey for in situ biogas upgrading by the addition of H2: Process performance and microbial insights." Applied Microbiology and Biotechnology 97(3): 1373-1381.

- Ryckebosch, E., M. Drouillon and H. Vervaeren (2011). "Techniques for transformation of biogas to biomethane." Biomass and Bioenergy 35(5): 1633-1645.

William H. L Stafford

Council for Scientific and Industrial Research (CSIR), South Africa

Title: Green economic development in the City of Johannesburg: production of biogas to fuel city buses

Time : 11:20-11:40

Biography:

William Stafford is a life scientist with R&D experience spanning twenty years. His research encompasses diverse fields of biochemistry, biotechnology, microbial ecology, systems biology, holistic resource management, industrial ecology, renewable energy and permaculture. As a senior researcher at the Council for Scientific and Industrial Research (CSIR), an overarching research question is: How can our natural resources be used sustainably for the benefit of all? Current research involves assessing various technology options, value-chains and alternate development scenarios to guide project and policy developments for the transition to a Green Economy and a more sustainable development path. Bioenergy is currently a research focus area that addresses a multiple development objectives; such as economic feasibility, social acceptance, environmental impacts and the allocation of biomass resources for the production of food, fuel, timber, chemicals and fibres in the growing Bio-economy.

Abstract:

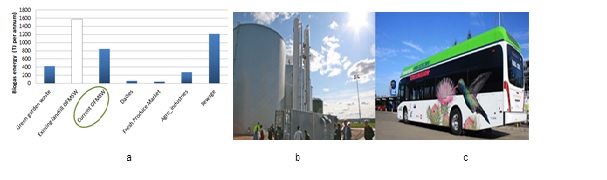

The City of Johannesburg has explored the opportunity of using biogas to fuel its buses in the drive to be low-carbon, resource efficient and socially inclusive. This study explored the feasibility of using biogas to fuel buses in the city of Johannesburg, South Africa. Biogas is a renewable fuel that can be used for electrical power, heating/cooling, and as a transport fuel. However, the use of biogas for transportation delivers more financial value-adding compared to using biogas for electricity- US$18/GJ for transport fuel and US$9/GJ for electricity. In addition, the use of biogas to fuel city buses has additional local benefits; such as reducing air pollution from vehicle tail-pipe emissions, reducing traffic congestion, and enhancing the social inclusivity of transportation. The cultivation of land and use of energy crops as feedstock for biogas production will require at least seven hectares per bus; which will place additional demands on the city’s scarce land resources and create potential conflicts with food production. Biodegradable wastes are alternative feedstock for biogas production that avoids these impacts and can be supplied at a cost that is currently competitive with the price of other transport fuels, such as diesel and petrol. However, the feasibility depends on the combined economies of scale for biogas production, upgrading and distribution; such that large-scale biogas production (>2000Nm3/h) is required to compete with petrol and diesel market prices. Using size-location modelling, we identified the optimal locations for two large biogas facilities that use the organic fraction of municipal solid waste as feedstock to produce upgraded biogas that can fuel up to six-hundred city buses. The benefits of this project include diverting organic waste from landfill, reducing carbon emissions, improving local air quality, increasing transportation efficiency, delivering new opportunities for transit orientated development and facilitating the transition to a Green economy.

Recent Publications:

- Amigun, B., Musango, J.K., and Stafford, W. (2011). Biofuels and sustainability in Africa. Renewable and Sustainable Energy Reviews, Vol. 15, Issue 2, Pages 1360-1372 doi:10.1016/j.rser.2010.10.015

- Stafford, W. Mapako, M. and Brent, A. (2011) Bioenergy Systems Sustainability Assessment and Management. Renewable Energy Law and Policy Review 3/2011: pp. 205-222

- von Maltitz, G.; Stafford, W (2011) Assessing opportunities and constraints for biofuel development in sub-Saharan Africa. CIFOR. Working Paper 58. Bogor, Indonesia. http://www.cifor.org/publications/pdf_files/WPapers/WP58CIFOR.pdf

- De Lange, W.; Stafford, W.; Forsyth, G.; and Le Maitre, D. (2011). Incorporating stakeholder preferences in the selection of technologies for using invasive alien plants as a bio-energy feedstock: Applying the analytical hierarchy process. Journal of Environmental Management Volume 99, 30 May 2012, Pages 76–83

- Stafford W., Cohen B., Pather-Elias, S., Von Blottnitz H., van Hille R., Harrison S., Burton S. (2013) Technologies for recovery of energy from wastewaters: Applicability and potential in South Africa. Journal of Energy in Southern Africa, 24 (1), pg 15-27.

- The economics of landscape restoration: Benefits of controlling bush encroachment and invasive plant species in South Africa and Namibia (2017). Ecosystem Services. In press http://dx.doi.org/10.1016/j.ecoser.2016.11.021

Dana Pokorna

University of Chemistry and Technology, Czech Republic

Title: Biogas desulfurization by autotrophic denitrification – temperature dependence

Time : 11:40-12:00

Biography:

Dana Pokorna is Assistant Prof. at the Department of Water Technology and Environmental Engineering, Faculty of Technology of Environment Protection, University of Chemistry and Technology Prague. Main areas of her interest are anaerobic biodegradation of organic substrates, determination of anaerobic biomass activity, analytical determination of byproducts and end products of anaerobic degradation, biogas cleaning (H2S removal), upgrading biogas to biomethan and transformation of CO2 to biomethan. She is the member of International Water Association (IWA) and European Federation of Biotechnology (EFB), the member of Czech Biogas Association and Czech Water Association and the member of the Czech Biotechnology Society Committee.

Abstract:

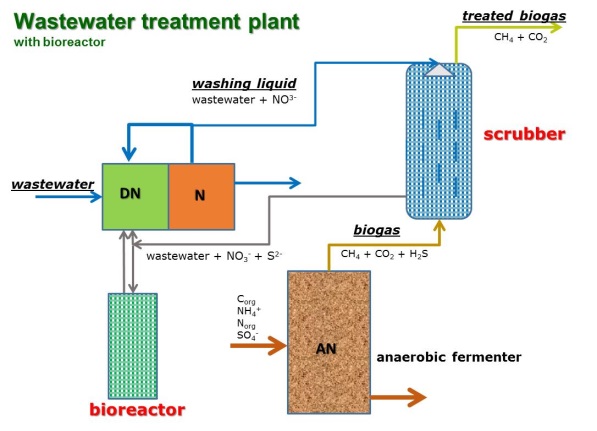

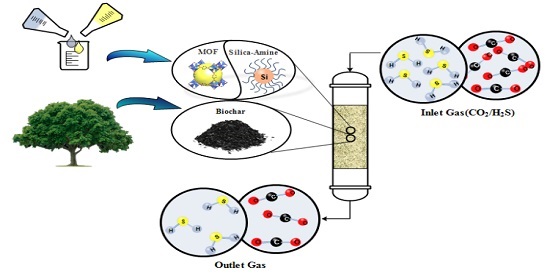

Biogas utilization is complicated when it contains hydrogensulfide coming from reduction of sulfur compounds during anaerobic digestion. There are many methods for desulfurization of biogas, but biological one based on activity of sulfur bacteria are advantageous from ecological and economical points of view. Our research was focused on the removal of hydrogensulfide from biogas by water scrubbing and on the treatment of washing liquid in a separate bioreactor with sulfur bacteria. The bioreactor was packed with a plastic carrier for immobilization of bacteria and operated in upflow mode so that sulfates were the final forms of sulfur. These bacteria can use oxygen or nitrates as electron acceptors during oxidation of sulfides and both oxidizing agents were studied. Process efficiency depends mainly on sulfide loading rate, dosed amount of oxygen, molar ratio S/N when nitrates were used, pH and temperature. In the case of nitrates addition bacteria of genus Paracoccus, Thiobacillus denitrificans and Thiobacillus thioparus were detected in biomass by FISH analysis. According to literature, the bacteria of genus Paracoccus have optimum for growth at high pH 6.5 – 10.5 and this fact was confirmed by our study, where bioreactor operation was stable and effective at pH over 10. Molar ratio S/N, which influences end products of autotrophic denitrification, has been set on value 0.55. The dependence of the process efficiency on temperature was studied for three temperatures: 20 °C, 25 °C and 30 °C and the highest loading rate of sulfides (350.9 mg·L-1·d-1) and N-NO-3 (258.6 mg·L-1·d-1) with sufficient efficiency was reached at temperature 30 °C. Our research has demonstrated the suitability of biological desulphurization of biogas in the external packed bed reactor with immobilized sulfur bacteria with oxygen and nitrate as oxidizing agents. Especially, desulfurization with nitrates can be advantageously included as autotrophic denitrification in the wastewater treatment line.

Recent Publications:

- Angelidaki I., G. Luo, and P. Kougias (2015). "Simultaneous hydrogen utilization and biogas upgrading by anaerobic microorganisms." Proceedings of 14th World Congress of Anaerobic Digestion, Viña del Mar, Chile, 15-18.11.2015, 2. biogas upgrading

- Díaz I., N. A., C. Pérez and F. Fdz-Polanco (2015). "Application of membrane modules to improve mass transfer for the chemoautotrophic biogas upgrading." Proceedings of 14th World Congress of Anaerobic Digestion, Viña del Mar, Chile, 15-18.11.2015.

- Gahleitner, G. (2013). "Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications." International Journal of Hydrogen Energy 38(5): 2039-2061.

- Luo, G. and I. Angelidaki (2013). "Co-digestion of manure and whey for in situ biogas upgrading by the addition of H2: Process performance and microbial insights." Applied Microbiology and Biotechnology 97(3): 1373-1381.

- Ryckebosch, E., M. Drouillon and H. Vervaeren (2011). "Techniques for transformation of biogas to biomethane." Biomass and Bioenergy 35(5): 1633-1645.

Rikke Lybaek

University of Roskilde, Denmark

Title: Deployment of a bio-economic ‘hub’ in rural Thailand by means of a Centralized biogas plant

Time : 12:00-12:20

Biography:

Rikke Lybæk has expertise in renewable energy planning and resource management in the transition from the use of fossil fuels to renewable energy sources. She specializes within the field of biomass utilization for the production of renewable energy, and work with concepts like bio-economy, industrial ecology and eco- efficiency. She has worked with e.g. biogas and thermal gasification technologies in many countries in Asia over the last 15 years, like Thailand, Malaysia, India and Japan, as well as within the EU. Her research focus is to establish decentralized energy systems in local communities based on indigenous biomass resources, and to apply a bottom up - a participatory approach - to the deployment of renewable energy technologies locally.

Abstract:

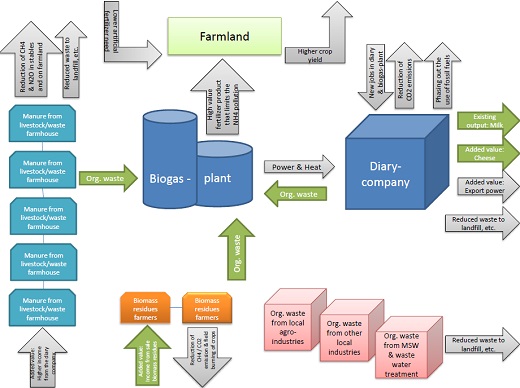

Statement of the Problem: This paper seeks to investigate the opportunities for implementing a Centralized biogas plant in Thailand, as a supplement to the existing Farm biogas plant concepts. This will be researched by identifying a subsector within the agriculture, where such type of plants would be valuable to deploy. Case studies of a local community; Tambon Ban Kor, in North East Thailand thus reviles that dairy cattle farmers, who deliver milk to a dairy company, could benefit extensively from such facility. The study indicates that current challenges regarding GHG emissions, manure handling practices, like spill of nitrogen, low milk yield and inappropriate cattle diets etc., can be improved on the cattle farms, by better housekeeping, as well as supply of manure to the local dairy. Here, fossil fuels use could be substituted by renewable energy from biogas, and the energy used at various temperature levels by cascading. The paper further reviles that large amount of appropriate and available feedstock for the suggested biogas plants are assessable within the community, and currently pose an environmental problem, or re-used inefficiently. The Centralized biogas plant will thus provide a development ‘hub’ for bio-economic solutions to evolve, and constitute to a platform for new income and product outputs opportunities, as renewable energy production as well as various environmental benefits within rural Thailand.

Recent Publications:

1. Municipalities as facilitators, regulators and energy consumers: enhancing the dissemination of biogas technology in Denmark. Lybæk, Rikke; Kjær, Tyge. International Journal of Sustainable Energy Planning and Management, Vol. 8, Nr. 2246-2929, 12.2015, p. 17.

2. Regional Supply of Energy from Small Scale Biogas Plants : Discovering alternative heat markets in Denmark. Lybæk, Rikke; Kjær, Tyge. GMSARN International Journal, Vol. 9, Nr. 1, 01.03.2015, p. 1-10.

3. Biogas Application Options within Milk Dairy Cooperatives in Thailand: Case Study Tambon Ban Kor, Khon Kaen. Lybæk, Rikke; Sommart, Kritapon . GMSARN International Journal, Vol. 10, Nr. 1, 10, 01.03.2016, p. 1-10.

4. Development, Operation, and Future Prospects for Implementing Biogas Plants. Lybæk, Rikke. Use, Operation and Maintenance of Renewable Energy Systems: Experiences and Future Approaches. red. /M.A. Sanz-Bobi (ed.). Vol. 111 Switzerland: Springer Publishing Company, 2014. p. 111-144 (Green Energy and Technology).

5. Methods for Prevention of Environmental Impacts. Christensen, Thomas Budde; Lybæk, Rikke; Kjær, Tyge. Situated Design Methods. red. /Jesper Simonsen; Connie Svabo; Sara Malou Strandvad; Kristine Samson; Morten Hertzum; Ole Erik Hansen. MIT Press, 2014. p. 339-356 (Design thinking, design theory).

Shiho ISHIKAWA

Hokkaido University, JAPAN

Title: Energy and economical evaluation of a biogas generation plant under the Feed-in Tariff scheme in Japan

Time : 12:20-12:40

Biography:

Shiho Ishikawa received a Masters degree in Agriculture from the Rakuno Gakuen University, Hokkaido, Japan in 2004 and a Ph.D. degree in Agriculture from the Hokkaido University in 2015. Following this, after working as an engineer at a private consulting company, she currently works for Hokkaido University, as an assistant professor and the Institute for laboratory where she is involved in several research projects related to smart grids. Currently she performs research on energy characteristics by using biogas generators for renewable energy resources and control algorithms for demand-side management on farm.

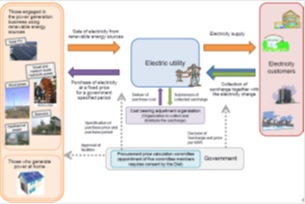

Abstract: