Day 2 :

Keynote Forum

Mohammed M. Farid

University of Auckland, New Zealand

Keynote: Converting Waste Products into Fuel and Useful Chemicals

Time : 09:00-09:25

Biography:

Mohammed Farid has completed his BE in Chemical Engineering from the University of Baghdad(1971), ME and PhD in Chemical Engineering from University of Swansea, Wales (1975 and 1977). He is Fellow of the Institution of Chemical Engineers, He has published more than 380 papers in international journals and refereed international conferences, 6 patents, 5 books, and 11 chapters in books. Professor Farid has received a number of international awards such as the Matsumae International Fellowship (1986), the Hisham Hijjawi Award (1993) and the Marie Curie Fellowship (2010). In 2010, he was short listed and came in the third place for the IChemE Innovator of the Year Award – sponsored by NES in the UK. He was invited as a keynote speaker to a large number of international conferences and to be in the editorial board of international journals.

Abstract:

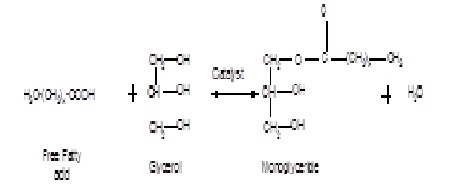

In this presentation, the possibility of converting low-grade vegetable oil or tallow available widely in New Zealand into biodiesel and energy materials will be discussed in an effort to improve the economy of this process. Currently established processes use alkali catalysts such as sodium hydroxide to trans-esterifies any source of lipid using methanol at low temperatures and pressures. However, the manufacturing cost of biodiesel produced remained high, making biodiesel more expensive that petroleum diesel, especially if high grade feedstock is used. Three possible approaches, which may improve the conversion of low grade lipid into biodiesel or useful chemicals, will be discussed in this presentation: development of gas phase reactor in which the trans esterification reaction takes place only in few seconds rather than many minutes. This is done by spraying the oil or molten tallow into fine droplet against methanol vapor at elevated temperatures, react glycerol, which is a waste product from the biodiesel manufacturing, with the free fatty acid present in the low grade tallow or oil according the esterification reaction shown. The produced monoglycerides can then be easily trans- esterified. This will prevent the harmful saponification reaction, which could consume the catalyst, and use of higher alcohol having higher solubility of the lipid to ease biodiesel production and also to produce energy materials, known as a phase change materials, that can be used to improve energy managements in buildings. In addition the potential of growing and harvesting algae in wastewater for the production of biodiesel will be also discussed.

Recent Publications:

- Farid, M.M. and Behzadi, s. “Method of Biodiesel Preparation” International Patent WO 2007/049979 A1, 3 May, 2007, US Patent 2009/0038209, Feb., 2009 and PCT/NZ 2006/000277.

- Behzadi, S. and Farid, M. “Title: Production of Biodiesel Using a Continuous Gas-Liquid Reactor, Bioresource Technology, 100,2, 2059-2062 (2008).

- Barzin R, Chen JJJ, Young BR, Farid MM. Application of PCM energy storage in combination with night ventilation for space cooling Applied Energy 158:412-421 Article number C Nov 2015.

- Mehrabadi A, Farid MM, Craggs R. Variation of biomass energy yield in wastewater treatment high rate algal ponds Algal Research 15:143-151 Article number C, 2016.

- Mehrabadi A1, Craggs R2, Farid MM3.Wastewater treatment high rate algal ponds (WWT HRAP) for low-cost biofuel production Bioresource Technology, Nov 2014. doi: 10.1016

Keynote Forum

Irene M C Lo

The Hong Kong University of Science and Technology, China

Keynote: Comparison of Different Options for Converting Food Waste to Biogas for Energy Uses using Life Cycle Assessment

Time : 09:25-09:50

Biography:

Irene M. C. Lo is currently a full professor in the Department of Civil and Environmental Engineering at The Hong Kong University of Science and Technology (HKUST) and has been joining HKUST since 1992. She received her Master and PhD degrees in Civil (Environmental) Engineering from the University of Texas at Austin. Prof. Lo is an elected Academician of the European Academy of Sciences and Arts (EASA). She is the first Hong Kong scholar inducted into the EASA. She is an elected Fellow of the Hong Kong Institution of Engineers (FHKIE), and elected Fellow of the American Society of Civil Engineers (FASCE). Prof. Lo has held 2 patents, edited 9 technical books, and published over 270 SCI journal articles and conference papers. Her research areas include solid waste treatment and management; magnetic nanomaterial-based technology for water and wastewater treatment; soil/sediment/groundwater remediation; and fate and transport of nanoparticles.

Abstract:

Food waste represents a major constituent of the municipal solid waste in urban cities while it can be used to produce useful products if well managed. In Hong Kong, the local Government has planned to employ anaerobic digestion to produce biogas from food waste. In consequence, the biogas produced can be converted into different forms of energy use, such as electricity and heat, city gas, and biogas fuel for vehicle use. It is essential to determine the best option for converting food waste based on their environmental performance so as to strive for a sustainable waste management system. In this study, life cycle assessment is conducted to evaluate the life cycle environmental performance of different food waste converting options (i.e., electricity and heat, city gas, and biogas fuel for vehicle use). The LCA is conducted using SimaPro 7.2.4 software with ReCiPe version 1.04 to evaluate both the impact and damage categories. For impact categories, climate change is the key impact category and it is found that biogas fuel as petrol substitute has achieved the best environmental performance compared to other converting options with -103.67 kg CO2e/tonne food waste. If 1,080 tonnes per day of food waste can be converted into biogas fuel as petrol substitute, approximately 2% of greenhouse gas emissions can be reduced in the transport sector in Hong Kong.

Recent Publications:

- Chiu, S.L.H. and Lo, I.M.C. (2016). Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environmental Science and Pollution Research, In press.

- Woon, K.S. and Lo, I.M.C. (2016). An integrated life cycle costing and human health impact analysis of municipal solid waste management options in Hong Kong using modified eco-efficiency indicator. Resources, Conservation and Recycling 107, 104-114

- Chiu, S.L.H., Lo, I.M.C., Woon, K.S. and Yan, D.Y.S. (2016). Life cycle assessment of waste treatment strategy for sewage sludge and food waste in Macau: perspectives on environmental and energy production performance. The International Journal of Life Cycle Assessment, 21(2), 176-189.

- Woon, K.S. and Lo, I.M.C. (2016). A Proposed Framework of Food Waste Collection and Recycling for Renewable Biogas Fuel Production in Hong Kong. Waste Management, 47, 3-10.

- Woon, K.S. and Lo, I.M.C. (2014). Analyzing Environmental Hotspots of Proposed Landfill Extension and Advanced Incineration Facility in Hong Kong using Life Cycle Assessment. Journal of Cleaner Production, 75: 64-74.

Keynote Forum

Kunio Yoshikawa

Tokyo Institute of Technology, Japan

Keynote: Development of portable ultraâ€small biomass gasification and power generation system

Time : 09:50-10:15

Biography:

Kunio Yoshikawa was born in 1953 in Tokyo, Japan. He is a professor of Tokyo Institute of Technology and an associate editor of Applied Energy. His bachelor, master and doctor degrees were awarded from Tokyo Institute of Technology. His major fields are energy conversion, waste management and environmental engineering. He has been working in Tokyo Institute of Technology for more than 38 years as a research associate, an associate professor and a professor. He has published nearly 200 journal papers with the major award of AIAA Best Paper Award, ASME James Harry Potter Gold Medal, JSME Environmental Technology Achievement Award and Best Educator Award of Tokyo Institute of Technology.

Abstract:

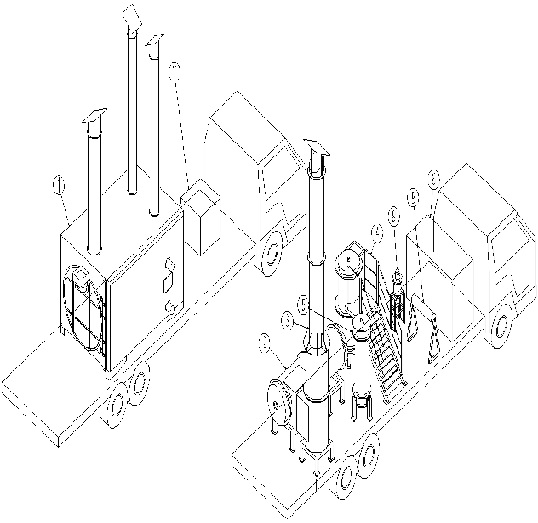

A portable and small-scale biomass gasification system has a potential for use in damaged areas by natural disasters (earthquake, flooding, Tsunami, etc.) or un-electrified rural areas in developing countries. However, the available feedstocks are usually high moisture content ones with different size, shape and properties. Therefore, some pretreatments are essential for efficient gasification of these feedstocks. In this study, woody biomass samples were first carbonized/torrefied by a carbonizer without usage of electricity. Then the carbonized/torrefied biomass were crushed and molded into briquette shape to be supplied into a fixed bed updraft gasifier. The syngas produced in the gasifier was first cleaned up by physical tar removal processes (the oil scrubbing, the centrifuge misty tar collection and the char bed adsorption) and was then supplied into a gas engine with 30kW electrical output. In the presentation, some detail results on the carbonization/torrefaction process, the briquetting process, the gasification process, the gas clean- up process and the gas engine operation will be presented. Then the mass balance and the energy balance of the total system will be analyzed to show the self-sustainability of this system. This work was supported by Innovative Science and Technology Initiative for Security, ATLA.

Recent Publications:

1. Hu Wu, Qi An, Yafei Shen, Noboru Harada, Lihao Chen and Kunio Yoshikawa (2015) The CO2 Gasification Kinetic Study of WEEE Plastic Char Derived from Medium Temperature pyrolysis. Energy and Environment Research 5: 82â€93.

2. Shunsuke Nakamura1, Siriwat Unyaphan, Kunio Yoshikawa, Shigeru Kitano, Shuji Kimura, Hiroyuki Shimizu and Kazuya Taira (2014) Tar removal performance of bioâ€oil scrubber for biomass gasification. Biofuels 5: 597â€606.

3. Yafei Shen, Peitao Zhao, Qinfu Shao, Dachao Ma, Fumitake Takahashi and Kunio Yoshikawa (2014) Inâ€situ catalytic conversion of tar using rice husk charâ€supported nickelâ€iron catalysts for biomass pyrolysis/gasification. Applied Catalysis B: Environmental 152â€153: 140â€151.

4. Bayu Prabowo, Kentaro Umeki, Mi Yan, Masato R. Nakamura, Marco J. Castaldi and Kunio Yoshikawa (2014) CO2–steam mixture for direct and indirect gasification of rice straw in a downdraft gasifier: Laboratoryâ€scale experiments and performance prediction. Applied Energy 113: 670â€679.

5. A. Paethanom P. Bartocci, B. D’ Alessandro, M. D’ Amico, F.Testarmata, N. Moriconi, K. Slopiecka, K. Yoshikawa and F. Fantozzi (2013) A low-cost pyrogas cleaning system for power generation: Scaling up from lab to pilot. Applied Energy 111: 1080-1088.

Keynote Forum

Boon Leong Lim

The University of Hong Kong, China

Keynote: Boosting bioenergy by coordinating the activities of chloroplasts and mitochondria

Time : 10:15-10:40

Biography:

Boon Leong Lim is an Associate Professor of the School of Biological Sciences at the University of Hong Kong. He obtained a B.Sc from the Chinese University of Hong Kong in Biochemistry (1990) and a Ph.D. degree from the University of Oxford (1994). Dr. Lim has published over 60 original articles and his current research interests focus on carbon flow of plants, plant organelle biology and Omics biology of plants. He has filed a few patents on agrobiotechnology and some of his patents have been successfully licensed to private companies.

Abstract:

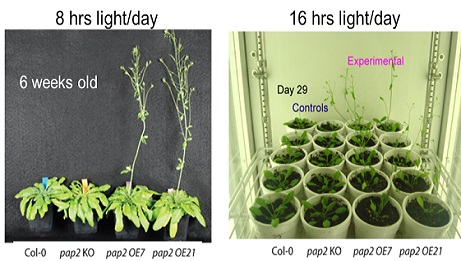

Increasing yield has been the ultimate goal of Agrobiotechnology and Biofuel industry for many decades. Current agrobiotech traits mainly rely on preventing yield loss, such as insect-resistance, herbicide resistance and drought resistance. Here we would like to show that manipulation energy outputs of chloroplasts and mitochondria can enhance plant growth and seed yield significantly. Overexpression (OE) of a purple acid phosphatase (AtPAP2) in Arabidopsis results in faster plant growth and higher seed yield (+40-50%). The OE lines contain significant higher ATP and sucrose levels than the wild-type (WT). Subcellular localization studies showed that this phosphatase is anchored on the outer membranes of the two energy generating organelles of plants, chloroplasts and mitochondria. Our data show that AtPAP2 affects the energy output from these two organelles by modulating import of certain nuclear-encoded proteins into chloroplasts and mitochondria, and thus affect their energy harvesting and energy conversion efficiencies, respectively. Based on the data of chlorophyll fluorescence measurement, transmission electron microscopy, 2D Blue Native/SDS-PAGE analyses, enzyme assays, oxygraph measurement, and proteomics analysis, we proposed a model to explain how AtPAP2 enhances sugar and ATP production in leaf cells of Arabidopsis thaliana by simultaneously coordinating the activities of chloroplasts and mitochondria. Homologous sequence of AtPAP2 can be found in the genome of some green algae. Our discovery may open up a new direction for Agrobiotechnology and bioenergy research.

Recent Publications:

- R. Zhang, … B. L. Lim (2016) AtPAP2 modulates the import of the small subunit of Rubisco into chloroplasts. Plant Signaling & Behavior. 11:e1239687

- C. Liang, …, B. L. Lim (2016) Transcriptomic, proteomic and metabolic changes in Arabidopsis thaliana leaves after the onset of illumination. BMC Plant Biology 16:43.

- C. Liang, …, B. L. Lim (2015) Impacts of high ATP supply from chloroplasts and mitochondria on the leaf metabolism of Arabidopsis thaliana. Frontiers in Plant Science 6:922.

- Y. Law, …, B. L. Lim (2015) Phosphorylation and dephosphorylation of the presequence of pMORF3 during import into mitochondria from Arabidopsis thaliana. Plant Physiology 169:1344-55.

- C. Liang, …, B. L. Lim (2014) Global small RNA analysis in fast-growing Arabidopsis thaliana with elevated concentrations of ATP and sugars. BMC Genomics 15:116.

- F. Sun, …, B. L. Lim (2013) Global transcriptome analysis of AtPAP2 - overexpressing Arabidopsis thaliana with elevated ATP. BMC Genomics 14:752-763.

- F. Sun, …, B. L. Lim (2012) AtPAP2 is a tail-anchored protein in the outer membrane of chloroplasts and mitochondria. Plant Signaling & Behavior 7:927-932.

- Y. Zhang, … B. L. Lim (2012). Over-expression of AtPAP2 in Camelina sativa leads to faster plant growth and higher seed yield. Biotechnology for Biofuels 5:19-28.

- F. Sun, … B. L. Lim (2012) A dual-targeted purple acid phosphatase in Arabidopsis thaliana moderates carbon metabolism and its overexpression leads to faster plant growth and higher seed yield. New Phytologist 194: 206

- Track 9: Biofuels

Track11: Bioethanol

Track 12: Biomass Technology

Location: Spain

Session Introduction

Markus Brautsch

University of Birmingham, Germany

Title: Duel Fuel Technology in Biomass CHP-Systems

Time : 10:40-11:00

Biography:

Markus Brautsch is Full Professor for Thermodynamics, Energy Technology and Renewable Energies at the Technical University of Applied Sciences Amberg-Weiden since 1998. He is the founder of the Institute of Energy Technology and the Bavarian Center of Excellence for Combined Heat and Power Generation. In 2014 he was appointed to a Guest Professor at the Jiangsu University of Science and Technology in China. He is guest lecturer at the Renewable Energy Center in Mithradam (India) and the University of Santa Caterina (Brazil).

Abstract:

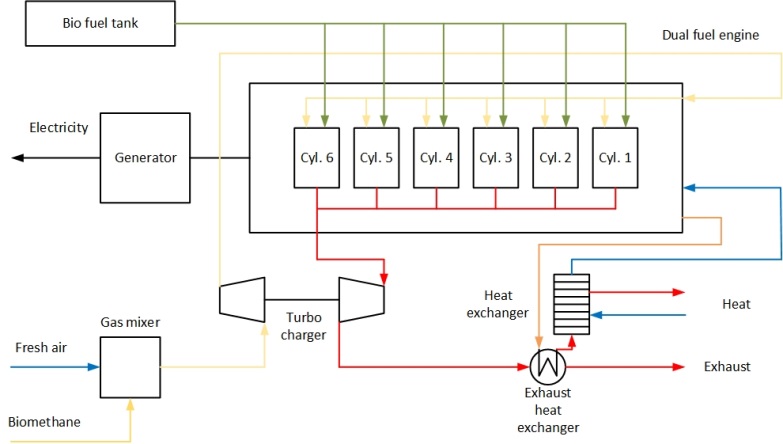

As a part of the research project “Comparison of CO2 mitigation costs of biomass CHP systems” a MAN common rail Diesel CHP system with 240 kW electrical and 230 kW thermal power was investigated in liquid fuel operation. Based on these initial measurements a dual fuel operation system with liquid and gaseous biogenous fuels was developed.

First, step the electrical efficiency, the thermal efficiency, the power coefficient and the emissions with different liquid biogenous fuels (rapeseed oil, soybean oil, biodiesel and palm oil) were investigated from part load to full load at compression rates of 19:1 and 16:1. The CHP system was driven under 100 % liquid fuel operation.

Second, biomethane was mixed with the combustion air to reduce the amount of liquid fuels to a minimum as “pilot fuel”. Beginning with 0 % (liquid fuel operation) the gas ratio was increased to its individual maximum. Investigations of the combustion behaviour by a cylinder pressure indicator system on each single cylinder attested a crucial influence of the point of the pilot fuel injection and the amount of pilot fuel. Hence, the biomethane ratio could be raised to its highest degree adapted to each different liquid biofuel.

As a result, different combinations of biomethane and biogenous liquid fuels were optimized in a highly efficient common rail Diesel CHP system. Compared to Gas-Otto CHP units, the dual fuel technology shows better electrical and thermal efficiencies as well as CO2 advantages.

Recent Publications:

- Lechner R., O´Connell N., Brautsch M.: Identifikation von Einsatzmöglichkeiten und der Zündstrahltechnologie zur Verbesserung der Anlageneffizienz und Wirtschaftlichkeit von BHKW-Anlagen mit experimentieller Überprüfung der Vorteile an einer Pilotanlage unter realen Bedingungen im Praxisbetrieb. Forschungsinitiative ZukunftBau, F 2943.Stuttgart: Fraunhofer-IRB-Verl. 2015

- Grünig G.: Zündstrahlmotoren – Effiziente Verbrennung von Biogas und Schwachgasen in Blockheizkraftwerken; 1. Auflage München; Süddeutscher Verlag onpact GmbH; 2010; ISBN 978-3-86236-008-6

- Bhaskor J. Bora, Ujjwal K. Saha: Optimisation of injection timing and compression ratio of raw biogas powered dual fuel diesel engine; Applied Thermal Engineering 92 (2016), 111-121

- Bhaskor J. Bora, Ujjwal K. Saha: Experimental evaluation of a rice bran biodiesel – biogas run dual fuel diesel engine at varying compression ratios; Renewable Energy 87 (2016), 782-790

- Debabrata Barik, S. Murugan: Experimental investigation on the behavior of a DI diesel engine fueled with raw biogas-diesel dual fuel at different injection timing; Journal of the Energy Institute 89 (2016), 373-388

Raphael Lechner

Technical University Amberg-Weiden, Germany

Title: Hydraulic Injection Characteristics of different Biofuels

Time : 11:20-11:40

Biography:

Raphael Lechner studied Environmental Engineering, Renewable Energies and Energy Efficiency at the Universities of Amberg and Kassel. He is head of R&D at the Institute of Energy Technology at the Technical University of Applied Sciences Amberg-Weiden and since 2014 director of the Bavarian Center of Excellence for Combined Heat and Power Generation.

Abstract:

As a part of a joint research project of the Centre of Excellence for combined Heat and Power and Fraunhofer UMSICHT, the hydraulic injection characteristics of various biofuels for diesel engine operation were investigated.

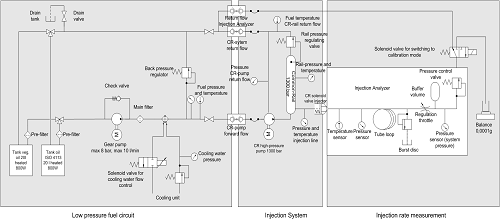

The measurements were carried out using a standard configuration common-rail injection system with a high pressure pump feeding into a common rail and a solenoid injector. The system was mounted on an injection system test bench, which was developed at the Technical University of Applied Sciences Amberg-Weiden (c.f. figure). The test bench features an IAV injection analyzer, which allows direct shot-to-shot measurement of injection rate and injection quantity for multiple injections per cycle, e.g. pre, main and post injection (c.f. [1],[2]).

The different biofuels investigated were pure rape seed oil, biodiesel, and crude bio-oil obtained from biogas digestate via Thermo-Catalytic Reforming (TCR®), a process developed at Fraunhofer UMSICHT (c.f. [3],[4],[5],[6]). Calibration fluid according to ISO 4113 was used as reference fuel.

The measurements were carried out at different rail pressures and injection durations in order to obtain the injector map for the different fuels. Additionally, measurements with different pre and post injection timings were performed to determine the closest possible timing of multiple injections according to the main injection.

The resulting injector maps clearly show the pressure dependency of injection quantities. Fuels with higher viscosity generally show considerable deviations from the reference fuel at lower injection pressures, whereas the differences diminish at higher injection pressures. Analysis of multiple injections shows that there is a minimum required lag time between the injection pulses to avoid converging of the individual injections. This lag time is generally higher when using fuels with higher viscosity.

Both phenomena indicate the need for recalibrating injector mappings and timings for engine operation when utilizing biofuels with fluid characteristics deviating from the reference fuel.

Recent Publications:

- Brautsch, M.; Lechner, R.: Common-Rail-Einspritzsysteme für Pflanzenöl-BHKW, University of Applied Sciences Amberg-Weiden Research Report 2008/2009, December 2008.

- Muntean, A.B. et.al.: Impact of different in-cylinder pressures on hydraulical performances of the diesel fuel injection systems, 15th International Conference on Experimental Mechanics, Porto 22-27 July 2012.

- Neumann, J. et.al.: Upgraded biofuel from residue biomass by Thermo-Catalytic Reforming and hydrodeoxygenation. Biomass and Bioenergy 89 (2016), p. 91-97.

- Neumann, J. et.al.: Production and characterization of a new quality pyrolysis oil, char and syngas from digestate – Introducing the thermo-catalytic reforming process. Journal of Analytical and Applied Pyrolysis 113 (2015), p. 137-142.

- Neumann, J. et.al.: The conversion of anaerobic digestion waste into biofuels via a novel Thermo-Catalytic Reforming process. Waste Management 47 (2016), p. 141-148.

- Conti, R. et.al.: Thermocatalytic Reforming of Biomass Waste Streams. Energy Technology 5 (2017), p. 104-110

Alberto Carmona Bosch

Abengoa Bioenergy, Spain

Title: Market view for Bioethanol: a Global perspective

Time : 11:40-12:00

Biography:

Alberto Carmona Bosch, 45, graduated at the University of Seville (Spain) and University of Paderborn (Germany) with a Bachelor in Economics and Business Administration and an Executive MBA from Institute San Telmo (partner school of IESE). Started working in Abengoa in 1999. Professional background in financial and commercial activities and promoting and financing renewable energy projects in Europe as well as acquisitions. He has been active in the international development of Bioethanol since 2005 with activities in The Netherlands, Brazil and U.S. He has lead global trading operations the last 12 years and has held several conferences in relation with Commodity markets, Ethanol markets and Risk Management.

Abstract:

Ethanol markets are mainly a function of local supply and demand and individual blending mandates. However there are non-mandatory markets that demand ethanol without the need of government intervention and purely for the octane value of Ethanol. Global trade flows appear not only because of supply and demand of the Big Three (US, Brazil and Europe) but also for many other different demands around the world. Crude prices and sugar prices play also a very important role in the price of ethanol and therefore in the market dynamics.

Even with the major opponents lobbying, whether 1G, 1.5G or 2G Ethanol continues its steady path forward as is the unique and quickest solution for reducing Greenhouse Gas emissions and improve air quality immediately.

Review of existing regulatory matters and proposals being discussed in the main Ethanol markets.

Kasalanati Prabhakar

Shymkent, Kazakhstan

Title: Pyrolysis of Coconut Shell and its Potential as Fuel

Biography:

Prabhakar is basically a post-graduate in agriculture. He pursued doctorate in biomass conversion technologies in Indian Institute of Technology Delhi, New Delhi, India. He worked in Acharya N G Ranga Agricultural University, Hyderabad, India as Professor. He has supervised thesis work of a number of research scholars in bioenergy and has a number of research papers to his credit. He contributed to the research in biomass conversion technologies mainly in pyrolysis of agricultural wastes and forest biomass. He designed a portable kiln for manufacturing charcoal at village level. He has experience in gasification of charcoal and smokeless stoves as well. In addition, he has experience in biofuels and solar power in irrigation systems.

Abstract:

The pyrolysis of coconut shell in experimental conditions at different temperatures for varying time periods, to determine the suitable range for obtaining maximum percentage yield of charcoal was studied. Pyrolysis under field conditions has been done to compare the percentage yield efficiency of charcoal with experimental results. The efficiency of pyrolysis in experimental conditions at a temperature of 300 degree Celsius and 180 seconds’ time duration is 70%, while in field conditions the efficiency recorded is 27%. Coconut shell with a yield potential of 2 tonnes per hectare per year in India can fulfil the cooking and heating requirements of two families, with five members each, in rural areas.

David Bolonio

Universidad PoliteÌcnica de Madrid, Spain

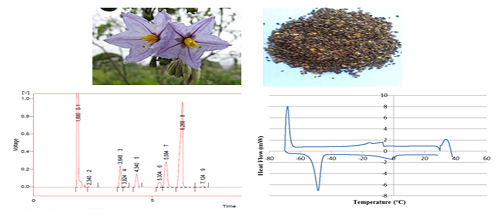

Title: Fatty acid methyl esters (FAMEs) obtained from rare seeds of Tunisia: Ibicella lutea, Peganum harmala, Smyrnium olusatrum, Onopordum nervosum and Solanum elaeagnifolium

Time : 12:00-12:15

Biography:

David Bolonio is in the third year of his PhD. He studied Mining Engineer and the Master in Environmental Research, Modeling and Risk Assessment at the Universidad Politécnica de Madrid. He has done research stays at the Faculty of Chemistry of the University of Graz and at the Joint Bioenergy Institute (Lawrence Berkeley National Laboratory). He has attended seven conferences presenting his research works and has published four papers in high impact journals.

Abstract:

The transport sector is a major energy consumer with the 27 % of the total energy used worldwide. This energy is almost completely provided by petroleum, a non-renewable resource that is concentrated in politically unstable countries and that causes global warming due to the greenhouse gas effect. Due to this situation, and the increase in the demand and the oil price, it is necessary to search for alternatives which may be used as transport fuels. One of the most viable alternatives are fatty esters, as they have similar properties to fossil fuels and they can be used as substitutes of conventional fuels without making big modifications to engines. This work aims to study the properties of fatty acid methyl esters (FAMEs) from Tunisian oils in order to assess their potential use as biofuel sources. The oils chosen for this study have been scarcely researched by other authors and are very interesting for a possible exploitation as fuels. Some of them are non-edible sources and all of them can be grown in arid places with no need of supplementary water: Ibicella lutea, Peganum harmala, Smyrnium olusatrum, Onopordum nervosum and Solanum elaeagnifolium. Their properties (cloud point, pour point cold filter plugging point, oxidation stability, cetane number, density, kinematic viscosity and heating value) have been predicted using equations that correlate the above properties with their ester profiles, measured with gas chromatography (GC-FID) and gas chromatography coupled with mass spectrometry (GC-MS), and crystallization onset temperature (COT), measured by differential scanning calorimetry (DSC). The work concludes with the comparison of the properties of the biodiesel obtained from these oils and the analysis of their possible use as biofuel sources.

Recent Publications:

- Neifar, M., Chouchane, H., Maktouf, S., Gara, J., Jaouani, A., & Cherif, A. (2016). Improved sugar yield for bioethanol production by modelling enzymatic hydrolysis of Peganum Harmala biomass through response surface methodology.

- Evergetis, E., & Haroutounian, S. A. (2014). Exploitation of apiaceae family plants as valuable renewable source of essential oils containing crops for the production of fine chemicals. Industrial Crops and Products, 54, 70-77.

- Arfaoui, M. O., Renaud, J., Ghazghazi, H., Boukhchina, S., & Mayer, P. (2014). Variation in oil content, fatty acid and phytosterols profile of Onopordum acanthium L. during seed development. Natural product research, 28(24), 2293-2300.

- Kolisis, F. N., Sotiroudis, T. G., & Sotiroudis, V. T. (2010). The potential of biodiesel production from fatty acid methyl esters of some European/Mediterranean and cosmopolitan halophyte seed oils. Journal of ASTM International, 7(3), 1-9.

- Bolonio, D., Llamas, A., Rodríguez-Fernández, J., Al-Lal, A. M., Canoira, L., Lapuerta, M., & GoÌmez, L. (2015). Estimation of cold flow performance and oxidation stability of fatty acid ethyl esters from lipids obtained from Escherichia coli. Energy & Fuels, 29(4), 2493-2502.

- Lapuerta, M., Rodríguez-Fernández, J., & Armas, O. (2010). Correlation for the estimation of the density of fatty acid esters fuels and its implications. A proposed biodiesel cetane index. Chemistry and physics of lipids, 163(7), 720-727.

Avanthi Althuri

Indian Institute of Technology - Kharagpur, India

Title: Simultaneous delignification and saccharification of mixed lignocellulosics for improved ethanol production in a single bioreactor: An eco-friendly enzymatic venture

Biography:

Althuri Avanthi, has graduated M.Tech under the guidance of Prof. Rintu Banerjee, IIT Kharagpur. Since 2012 she is pursuing PhD under same Professor at IIT Kharagpur. She is availing DBT scholarship since 2012 and had received GATE 2010-12 fellowship. Her current doctoral dissertation topic deals with biomass and biofuels with special emphasis on bioethanol production from holocellulosic stream of mixed lignocellulosic biomass.

Abstract:

Lignocellulosic ethanol is the energy of the future that has the potential to replace petro-fuels when driven by a simple and competent biomass processing technology[1,2]. In the midst of alarming environmental consequences of industrialization and excessive fossil fuel combustion, it is obligatory to seek for a greener and benign approach for 2G ethanol production[3]. The present study is one such attempt that deals with enzymatic processing of carbon neutral lignocellulosics. For this a blend of nonedible lignocellulosics namely, Ricinus communis, Saccharum officinarum tops and Saccharum spontaneum was taken as a substrate, since collection of a single type of biomass to feed a refinery is time consuming, laborious and cost intensive. Whereas mixed feedstocks are readily available, sustainable and moreover are tailor made to fit in the best biochemical composition[4]. Biomass blend considered showed high carbon% and energy density[5].

The present study involved simultaneous biomass pretreatment and hydrolysis using a cocktail of enzymes consisting of ligninolytic laccase from Pleurotus djamor and a complete holocellulolytic system from Trichoderma reseei RUT C30 consisting of endo-glucanase, exo-glucanase, β-glucosidase and xylanase for hydrolysis. This enzyme based simultaneous pretreatment-saccharification (SPS) of biomass was found to yield higher reducing sugars (633 mg/g) than sequential pretreatment-saccharification (SePS, 600 mg/g), chemical pretreatment-saccharification (CPS, 367 mg/g) and chemical pretreatment-enzymatic saccharification (CPES, 526 mg/g). Ethanol concentration from co-fermentation of sugars was observed to be 7.1% (v/v). Further improved ethanol concentration up to 7.65% (v/v) was observed when biomass was subjected to SPS for 2h and followed by co-fermentation in same vessel. Statistical model was used to evaluate and validate the performance of this partially consolidated bioprocessing (PCBP). Biomass to ethanol conversion was 26.5% (g/g) with 60.35 g/L ethanol. The adopted process has meagre allied waste streams and thus aids in safeguarding the environment for future generations.

Sanjeev Kumar

Indian Institute of Technology, Kharagpur, India

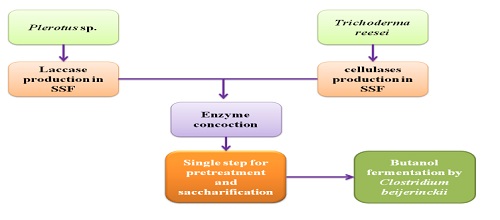

Title: A challenging attempt towards utilization of non-edible lignocellulosics for cost-effective biobutanol production

Time : 12:15-12:30

Biography:

Sanjeev Kumar, PhD student is working under the esteemed guidance of Prof. Rintu Banerjee at Advanced Technology Development Center, Indian Institute of Technology, Kharagpur, India. He is working on second generation biobutanol production using Clostridium beijerinckii.

Abstract:

Global raise in the living standards of the society throughout the world has created a huge demand for transportation fuel. Conventionally energy demand used to be met through the use of fossil fuels but due to environmental concerns, sustainable sources of fuels are being researched upon nowadays. In this venture, biofuels have gained immense popularity since they are carbon neutral and has the potential to fulfill the demand1. Nowadays pretreatment and saccharification of lignocellulosics is performed sequentially in order to obtain fermentable sugar for biofuels production2,3. In the present study, pretreatment and saccharification was investigated concomitantly to obtain reducing sugars from bamboo using laccase and cellulases extracted from solid state fermentation of Pleurotus sp. and Trichoderma reesei respectively. One of the main advantages of this process is the overall time reduction since pretreatment and saccharification is conducted simultaneously. Laccase assists in increasing cell wall permeability by degrading the lignin and thus facilitated the diffusion of enzymes into the cell wall to cause hydrolysis of holocellulose for the production of fermentable sugars. Process parameters governing the system viz., temperature, incubation time, pH, cellulase: laccase ratio in the enzyme cocktail and solid loading were optimized using response surface methodology thus producing a maximum reducing sugar content of 75.45 g/L. HPLC analysis revealed that broth has mixtures of glucose (36.89%), pentoses (24.29%) and cellobiose (38.81%). The potential of these sugars was analyzed using Clostridium beijerinckii by converting the sugar rich broth into butanol4. Clostridia have the capability to utilize C6, C5 and disaccharide sugars

Recent Publications:

- Procentese, A., Raganati, F., Olivieri, G., Russo, M.E., Marzocchella, A., 2017. Pre-treatment and enzymatic hydrolysis of lettuce residues as feedstock for bio-butanol production. Biomass Bioener. 96, 172–179.

- Ma, K., Ruan, Z., 2015. Production of a lignocellulolytic enzyme system for simultaneous bio-delignification and saccharification of corn stover employing co-culture of fungi. Bioresour. Technol. 175, 586–593.

- Dhiman, S.S., Haw, J., Kalyani, D., Kalia, V.C., Kang, Y.C., Lee, J., 2015. Simultaneous pretreatment and saccharification: green technology for enhanced sugar yields from biomass using a fungal consortium. Bioresour. Technol. 179, 50–57.

- Kumar, S., Gujjala, L.K.S., Banerjee, R., 2017. Simultaneous pretreatment and saccharification of bamboo for biobutanol production. Ind. Crops Prod. (Accepted)

- Al-Shorgani, N.K.N., Isa, M.H.M., Yusoff, W.M.W., Kalil, M.S., Hamid, A.A., 2016. Isolation of a Clostridium acetobutylicum strain and characterization of its fermentation performance on agricultural wastes. Renew. Energy, 86, 459–465.

- Track 1: Biomass feed stocks for renewable energy generation

Track 2: Biomass

Track 3: Bioenergy Conversion

Location: Spain

Session Introduction

Richard Sayre

Los Alamos National Laboratory, USA

Title: Improving Photosynthetic Efficiency and Biomass Yield in Plants and Algae

Time : 14:30-14:50

Biography:

Richard Sayre is a Senior Research Scientist at Los Alamos National Laboratory (LANL) and the New Mexico Consortium (NMC). Dr. Sayre’s research interests include; enhancing photosynthetic efficiency, algal and plant biotechnology, and nutritional biofortification of crop plants. Dr. Sayre has directed several large research consortia including: 1) Phase I of the BioCassava Plus Program funded by the Bill and Melinda Gates Foundation. 2) Center for Advanced Biofuel Systems, a Dept. of Energy (DOE) Energy Frontier Research Center focusing on generating advanced biofuels from algae and plants. 3) Scientific Director of the National Alliance for Advanced Biofuels, and Bioproducts, the largest DOE-sponsored algal biofuels consortium funded to date; and 4) Director of the PACE (Producing Algae for Energy and Coproducts) targeted algal biomass and bioproducts program.

Abstract:

One of the more environmentally sustainable ways to produce high energy density (oils) liquid transportation fuels is photosynthetic reduction of carbon dioxide into carbohydrates and hydrocarbons and their subsequent conversion into fuels. Photosynthetic carbon capture from the atmosphere combined with bioenergy production (combustion) and subsequent carbon capture and sequestration (BECCS) has also been proposed by the recent Intergovernmental Panel on Climate Change Report as the most effective and economical way to remediate atmospheric greenhouse gasses. To maximize carbon capture efficiency and energy-return-on-investment, we must develop cropping systems that have the greatest aerial biomass yields with the lowest inputs. All photosynthetic organisms, however, convert only a fraction (< 5%) of the solar energy they capture into harvestable chemical energy (reduced carbon or biomass). To increase aerial carbon capture rates and biomass productivity it will be necessary to increase photosynthetic efficiency in plants and algae. We will discuss metabolic engineering strategies to improve photosynthetic efficiency and biomass productivity in algal and plant systems, often borrowing metabolic strategies from one photosynthetic system to transfer into another. These strategies include optimization of photosynthetic light-harvesting antenna size and the introduction of algal inorganic carbon concentrating systems into plants to increase carbon fixation efficiency and biomass yields. To date, these strategies have resulted into up to two-fold increases in biomass productivity in algae and crop yields in outdoor field trials.

References:

- Olivares J, et al. (2016) Review of the algal biology program within the National Alliance for Advanced Biofuels and Bioproducts. Algal Res. DOI: 10.1016/j.algal.2016.06.002.

- Kumar A, Perrine Z, Stroff C, Postier BL, Coury DA, Sayre RT and Allnutt FCT (2016) Molecular Tools for Bioengineering Eukaryotic Microalgae. Curr. Biotechnol. 5:93-108.

- Negi S, Barry AN, Friedland N, Sudasinghe N, Subramanian S, Pieris S, Holguin FO, Dungan B, Schaub T and Sayre RT (2015) Impact of nitrogen limitation on biomass, photosynthesis, and lipid accumulation in Chlorella sorokiniana. J. Appl. Phycol. DOI 10.1007/s10811-015-0652-z.

- Subramanian S, Barry A, Pieris S and Sayre RT (2013) Comparative energetics and kinetics of autotrophic lipid and starch metabolism in chlorophytic microalgae: Implications for biomass and biofuel production. Biotechnol. Biofuels 6: 150-162.

- Perrine Z, Negi S and Sayre, RT (2012) Optimization of photosynthetic light energy utilization by microalgae. Algal Res. 1:134-142.

- Blankenship RE et al., (2011) What is the solar energy conversion efficiency of natural photosynthesis compared to photovoltaic cells? Science 332:805-809.

Ralph-Uwe Dietrich

German Aerospace Center, Germany

Title: Alternative fuels from Biomass and Power (PBtL) – A case study on process options, technical potentials, fuel costs and ecological performance

Time : 14:50-15:10

Biography:

Ralph-Uwe Dietrich leads the research area Alternative Fuels at the Institute of Engineering Thermodynamics at the German Aerospace Center (DLR) in Stuttgart. He is responsible for the research group on techno economic and ecologic evaluation of alternative fuels for aviation and global transport. He received his PhD in Engineering at the Technical University Clausthal in 2013 as a Scientific coworker at the Clausthaler Umwelttechnik Institute (CUTEC-Institut GmbH). Before that, he got 15 years of project manager experience at different enterprises (SME and Fortune 500) of the process and automation industry.

Abstract:

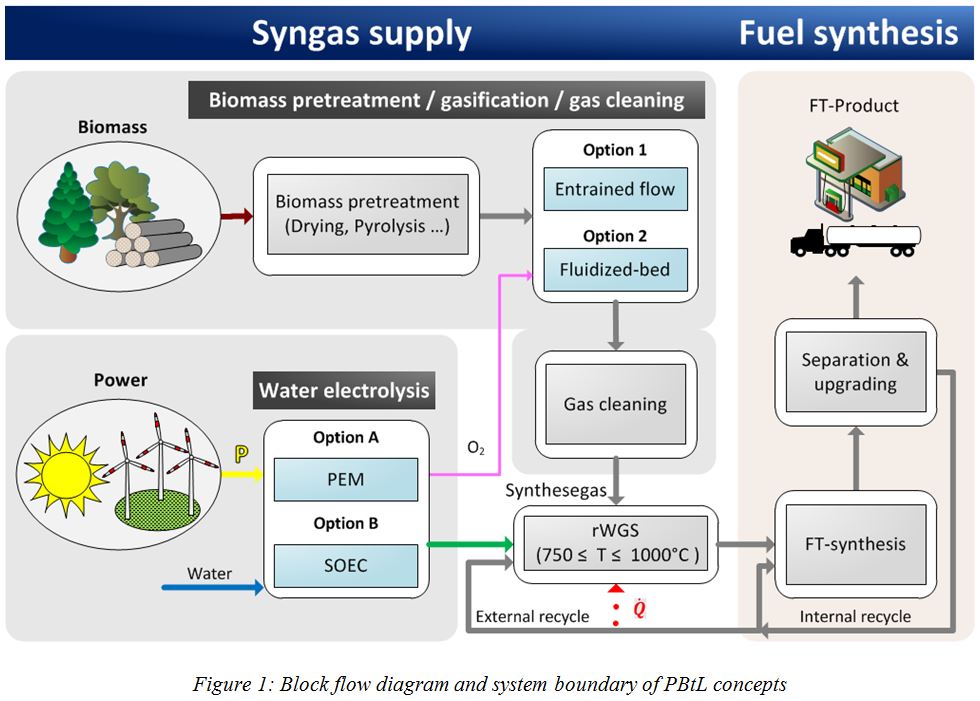

Greenhouse gas emissions in the transport sector shall be reduced to reach globally agreed COP21 goals. One option is to replace fossil based fuels with bio-based alternatives. The technical potential of biofuels made from energy crops (1st generation), biomass and waste wood (2nd generation) typically suffer from the limited technical potential of biomass resources in central Europe. Biofuel output can significantly be increased in the Power&Biomass-to-Liquid (PBtL) concept utilizing renewable electricity in modified BtL plants. The case study presents detailed results on promising process configurations of Fischer-Tropsch PBtL concepts based on different gasifiers and electrolyzers in terms of fuel production potentials, fuel costs and CO2 footprint.

Results from the study indicate that the biomass specific fuel output can be quadrupled when utilizing green electricity for hydrogen generation in the PBtL process. The increased fuel output results in lower fuel production costs due to the effects of the economy of scale. Fuel production costs below 1.3 €/l were estimated for a large PBtL plant (225 kt/year) assuming an electricity price of 31.4 €/MWh (average EEX-Phelix index of the year 2015). The exergy analysis reveals that the electrolysis and the gasification processes are characterized by the most significant thermodynamic optimization potentials. The PBtL concept is characterized by a lower CO2 footprint, as high carbon conversion rates close to 100 % can be achieved by using oxy-fuel technology and recycling the entire CO2 within the system. Hence, largest CO2 emissions arise from harvesting and transportation of the biomass feedstock.

Recent Publications:

- Albrecht, F, König, D, Baucks, N, Dietrich, R.-U. (2017) A standardized methodology for the techno-economic evaluation of alternative fuels – A case study. Fuel – The Science and Technology of Fuel and Energy, 194:511-526.

- Albrecht, F, Zhang, J, Dietrich, R.-U. (2016) Process design and economic assessment of converting CO2 to liquid fuels. ACI's 7th Carbon Dioxide Utilisation Summit 2016, 19.-20. Okt. 2016, Lyon, France.

- Albrecht, F, Dietrich, R.-U., König, D, Seitz, A, Thess, A (2016) Techno-Economic Assessment of the Production of Synthetic Jet Fuel from Carbon Sources and Renewable Hydrogen. GREENER AVIATION 2016, 11.-13. Oct. 2016, Brussels, Belgium

- Albrecht, F, König, D, Dietrich, R.-U. (2016) The potential of using power-to-liquid plants for power storage purposes. In: 2016 13th International Conference on the European Energy Market (EEM), S03_10163. IEEE Xplore Digital Library

- König, D, Freiberg, M Dietrich, R.-U. Wörner, A (2015) Techno-economic study of the storage of fluctuating renewable energy in liquid hydrocarbons. Fuel – The Science and Technology of Fuel and Energy, 159:289-297

Souman Rudra

University of Agder, Norway

Title: Effects of variable feedstock particle size on Birchwood gasification: A CFD approach

Time : 15:10-15:30

Biography:

Souman Rudra is currently working at the University of Agder, Norway as an associate professor since 2013. He conducts research and teaching within renewable energy technology - related to biomass conversion process and thermal energy systems and analysis of energy conversion systems in general. He has his expertise in design, modeling, and simulation of the different energy system specially bio-energy system. Several articles have been published in this area. Energy and exergy analysis, LCA analysis have also done for several of his design energy systems. Based on those analyses, he has proposed a quad-generation model for producing power, heat, cooling and SNG (synthesized natural gas).

Abstract:

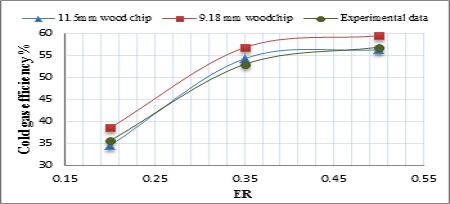

Gasification is a complex process and determining gasification characteristics experimentally is a time-consuming process. Using CFD models to predict and examine about gasification characteristics, in the various scenario can be time saving and safe. This paper primarily discusses the results of a CFD model, which simulates gasification characteristics of Birchwood. During the work, a variation of producer gas yield, syngas composition and cold gas efficiency of the syngas were investigated with a variable biomass particle size. A 3D CFD model of a fixed bed downdraft gasifier has been developed. Euler –Euler approach has been used to model the gas phase reactions while Lagrangian approach has been used to model the solid- gas reactions. For the simulations, biomass (Birchwood) particles with two different diameter sizes were used. They were 11.5mm and 9.18 mm. In this work, gasification parameters were examined within the equivalence ratio (ER) range from 0.2 to 0.5. The simulated results were validated using the actual fixed bed downdraft gasifier available at UIA, Norway. CO, CO2, CH4 and H2 mass fractions of the syngas were measured along with the calculated values of syngas yield and cold gas efficiency (CGE). With the 9.18mm diameter birchwood particle, CGE has shown an average maximum value of 59.4 % at the ER value of 0.5, which is a 4% improvement over the 11.5mm diameter biomass particle. In addition, Syngas yield has also shown an average maximum value of 2.8 Nm3/h with the 9.18 mm wood particle, which is an improvement of 0.1 Nm3/h over the 11.5 mm biomass particle.

Recent Publications:

- Prabir Basu. (2010). Biomass Gasification and pyrolysis Practical Design and Theory. ELSEVIER. (ISBN- 0080961622).

- Pratik N. Sheth, Babu BV. (2009) Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresource Technology 100:3127–3133.

- Keran D. Patel, Shah NK, Patel RN. (2013) CFD Analysis of Spatial Distribution of Various Parameters in Downdraft Gasifier. Procedia Engineering 51: 764-769.

- Gerun L, Paraschiv M, Vijeu R, Bellettre J, Tazerout M, Gøbel B, Henriksen U. (2008) Numerical investigation of the partial oxidation in a two-stage downdraft gasifier”, Fuel 87:1383

- Sarker S, Nielsen HK (2015) Preliminary fixed-bed downdraft gasification of birch woodchips. International journal of environmental science 12: 2119

- Souman Rudra, Lasse Rosendahl, Morten B. Blarke. (2015) Process analysis of a biomass-based quad-generation plant for combined power, heat, cooling, and synthetic natural gas production. Energy Conversion and Management 106: 1276–1285

Xiaolei Zhang

Queen’s University Belfast, UK

Title: Theoretical elucidation of the molecular behaviour of levoglucosan during biomass pyrolysis

Time : 15:30-15:50

Biography:

Xiaolei Zhang is a Lecturer at the Queen’s University Belfast (QUB), UK since January 2015. She received a PhD in May 2013 from the Royal Institute of Technology (KTH), Sweden on the topic of quantum mechanics investigation of bioenergy systems and she has worked as a researcher at University of Alberta, Canada on process modelling of bioenergy system for 14 months. Rich international research achievements of Dr Zhang are reflected by the authored 20 peer-reviewed publications in leading international journals in the area of Energy, with over 200 citations and an H-index of 9 on Scopus; together with the delivery of 22 invited talks, lectures, and other conference contributions.

Abstract:

The bio-fuels and bio-chemicals derived from lignocellulosic biomass are popularly referred to as second-generation bio-fuels or bio-chemicals. As a valuable chemical material, levoglucosan is one important primary product during cellulose pyrolysis either as an intermediate or as a product. The fundamental investigation on the mechanism and kinetic modelling of the production of levoglucosan from lignocellulosic biomass has been carried out. Three available mechanisms for levoglucosan formation have been studied theoretically by performing density functional theory based calculations. Specifically, the molecular behaviour of levoglucosan has elucidated by revealing 14 reaction pathways, 26 elemental reaction steps, and the involved around 60 compounds act as intermediates, transition states, or products. By comparing with the activation energy obtained from the experimental results, it was concluded that levoglucosan chain-end mechanism fits better with the experimental data for the formation of levoglucosan. The variational transition state rate constants for every elementary reaction and every pathway were calculated. The first-order Arrhenius expressions for these elementary reactions and pathways were suggested. Furthermore, this research provides techno-economic assessment of the available routes for the production of levoglucosan and its derived products, and the paper will be concluded by identifying key challenges and future trends for second-generation bio-chemicals. It also confirms that Quantum Mechanics based simulation can reveal fundamental phenomena, which are difficult to be explored from traditional experimental techniques, and can be used to guide the experimental design and industrial application.

Recent Publications:

- Zhang, X. (2016), Essential scientific mapping of the value chain of thermochemical converted second-generation bio-fuels. Green Chemistry. 18, 5086-5117

- Zhang, X., Kumar, A., Oestreich, D., Arnold, U., and Sauer, J. (2016). An optimization process design for woody biomass gasification with further upgrading into oxymethylene ethers. Biomass and Bioenergy. 90, 7–14.

- Zhang, X., Yang, W. and Blasiak, W. (2013). Kinetics Study on Thermal Dissociation of Levoglucosan during Cellulose Pyrolysis. Fuel, 109, 476–483.

- Zhang, X., Yang, W. and Blasiak, W. (2013). Levoglucosan Formation Mechanisms during Cellulose Pyrolysis. Journal of Analytical and Applied Pyrolysis, 104, 19–27.

- Zhang, X., Yang, W. and Blasiak, W. (2012). Kinetics of levoglucosan and formaldehyde formation during cellulose pyrolysis process. Fuel, 96(0), 383–391.

Khalid FARES

Cadi Ayyad University-Marrakech, Morocco

Title: Quality of organic amendment obtained from organic waste fraction in old landfill

Time : 15:50-16:10

Biography:

Khalid Fares is Professor Teacher Researcher at Cadi Ayyad University (Department of Biology), Marrakech, Morocco. He is the Head of Biochemistry and Biotechnology of Plants Unit, President of the “Federation of African Societies of Biochemistry and Molecular Biology” and Former President of the “Moroccan Society of Biochemistry and Molecular Biology. Pr FARES is member of Moroccan Society of Biosafety as well as many professional bodies. He is also Reviewer for European Journal of Agronomy, Carbohydrate Research, Annals of Applied Biology, Journal of Agricultural and Food Chemistry and Acta Agriculturae Scandinavica. His research in the field of Food Science and Biochemistry as well as the valorization of waste was published in several journals and communicated in many international congresses. Pr FARES was the organizer of many international meeting and congresses.

Abstract:

18 000 tons of solid household wastes are produced daily in Morocco and joined generally the dump sites which reach the optimal capacity and needs therefore to be closed through rehabilitation programme. Morocco has recently undertaken a vast controlled landfill construction program and rehabilitation of old dumps. This rehabilitation is based mainly on the land filling of all wastes and construction of green spaces without any recycling or valorization of the organic part of these wastes which may constitutes a big proportion. The present work aims to determine the physicochemical and microbiological characteristics of organic substrates in the old landfill in order to use it as an organic amendment. Three samples of 100 kg each were taken from the landfill of Sidi Bennour, sieved later and the organic substrates fraction (OSF) was an analyzed chemically and microbiologically. The OSF represents 65 % in weight. This OSF was stable and hygienic especially when sugar beet lime sludge (SBLS) is added: the pH value was reduced to 8.4, the C/N ratio to 12 and no microorganism pathogen was detected. The concentrations of heavy metals were lower than the limit values ​​recommended. The germination test using aqueous extracts of the OSF showed no phytotoxicity for all plant tested. Tests on radish crop showed the lack of any toxicity and gave a good production yield. The addition of sugar beet lime sludge to the OSF and the reuse of this substrate as organic amendment could be considered as sustainable solution for the rehabilitation of the old landfill.

Santosh Sankh

Reliance Technology Group, Reliance Industries, India

Title: Alkaline pretreatment and saccharification of woody biomass: Castor Stalk

Time : 16:30-16:50

Biography:

Santosh kumar Sankh is working as senior scientist at Reliance Industries, Mumbai. He is having experience in Biofuels, biomass deconstruction research.

Abstract:

Efficient pretreatment of lignocellulosic biomass to sugars is currently needed for viable biofuel production technology. This study investigates the efficiency of alkaline pretreatment for the saccharification of woddy biomass, castor stalk. Alkaline pretreatment by using sodium hydroxide (NaOH) is capable of maintaining the highest cellulose recovery and enzymatic hydrolysis. The optimized conditions of NaOH pretreatment includes biomass load 8 % (w/v), NaOH concentration 1% (w/v), pretreatment temperature 121°C and pretreatment time 15 min. The enzymatic hydrolysis using 50 FPU of enzyme at a biomass load of 5 % (w/v) gave a hydrolysis of 46.78 % in 24 h.

Sonia Shilpi

University of Newcastle, Australia

Title: Methane production through anaerobic digestion of various energy crops irrigated with wastewaters

Time : 16:50-17:05

Biography:

Sonia Shilpi is a PhD student of University of Newcastle, NSW, Australia. She has been working on ‘Wastewater driven biomass production for energy generation’ as of her Ph.D. Program. She has completed a set of exciting experiments including “Methane production through anaerobic digestion of various energy crops irrigated with wastewaters”. She has contributed to several publications and conference presentations from her research work.

Abstract:

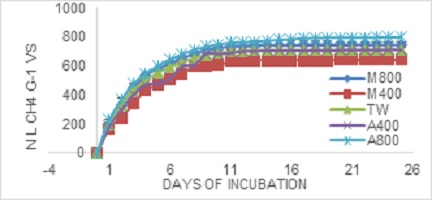

It is essential to develop sustainable energy supply systems that aim to consolidate the energy demand from renewable sources and also mitigate the emission of greenhouse gases. Biogas production is a key technology for the sustainable use of biomass as renewable energy source. High energy yields per hectare can be achieved through biogas production by using a wide range of energy crops. Maize, sunflower and Sudan grass are the most commonly used energy crops. The field experiment covered five different types of energy crops grown using two types of wastewaters viz. Abattoir (AWW) and municipal wastewater (MWW) at two different irrigation rates (400mm and 800mm) and tap water (TW). Dry biomass yield (DBY) was assessed from a field plot experiment at St. Kilda, South Australia. Total solids (TS) and volatile solids (VS) were determined on fresh biomass samples. DBY data obtained from the field trial (all five crops) increased with increasing wastewater irrigation. The plots irrigated with AWW 400 and 800 mm showed significantly higher yield than the MWW (400 and 800 mm) and TW (800mm) irrigated plots. The amount of biogas production was monitored every day and expressed as norm litre per kg of volatile solids (Nl kg-1 VS). Anaerobic digester was used to determine a reference methane yield for finely ground substrates under optimal conditions. Inoculum was obtained from a bolivar plant, Salisbury city council. Substrate/inoculum ratio based on volatile solid (VS) basis was used in all batch experiments, performed in 500 ml bottles (working volume 400 ml) in triplicate, incubated on a shaking water bath (70 rounds minute-1 (rpm)) at 37±1°C, and continued until methane production became negligible (<5 ml CH4 d-1). The methane yield per hectare was calculated by multiplication of the biomass yield and the specific methane yield. To be able to run biogas plants economically the methane yield from energy crops needs to be known. The present data show that the methane yield of energy crops depends on their nutrient composition. Maize (A800) exhibited the highest value in terms of potential methane yield (798.23 Nml CH4 g−1 VS).

Recent Publications:

- Sonia Shilpi, Balaji Seshadri, Nanthi S Bolan and Ravi Naidu. (2015). Phytotoxicity of wastewater irrigation in solution, sand and soil medium. "CRC CARE-2015. ‘Clean-up Conference”.

- S. Shilpi, M. Nuruzzaman, Fahmina Akter, M.N. Islam and G.N.C. Sutradhar. 2014. Response of Nitrogen and Sulfur on the Oil content and Nutrient status of Soil. International Journal of Bio-resource and Stress Management. 5(1):041-046.

- A. Husna, M. A. Maih, S. Begum, S. Z. Shilpi and M. R. Islam. 2014. Genetic Variability, Correlation And Path Co-Efficient Analysis Based On Vegetative Characters In Bottle Gourd (Lagenaria Siceraria L.). Advance in Agriculture and Biology. 2 (1): 8-12.

- F. Akhter, M. N. Islam, A.T.M. Shamsuddoha, S. Islam and S. Shilpi. 2013. Response of Phosphorus and Sulphur on the Growth and Yield of Soybean. International Journal of Bio- resource and Stress Management. 4(4):556-561.

- S. Shilpi, M.N.Islam, G.N.C.Sutradhar, A.Husna and F. Akhter. 2012. Effect of Nitrogen and Sulfur on the Growth and Yield of Sesame. International Journal of Bio-resource and Stress Management. 3(2): 177-182.Harper C (2009) The neuropathology of alcohol-related braindamage. Alcohol Alcohol 44:136-140.

Bobbo Nfor Tansi

BTU Cottbus, Germany

Title: Prospects and Barriers for the Sustainable Use of Second Generation Biomass from the Palm Oil Industry

Time : 17:05-17:20

Biography:

Bobbo Nfor Tansi is a PhD student at the Brandenburg Technical University Cottbus Germany. He is currently researching on “Analyzing the calorific and sustainability potential of Cameroonian palm oil residues for co firing in power plants. As a PhD student he has been assisting as a student lecturer at his university, offering courses in energy security and sustainability. Mr. Tansi has since May 2016, been teaching courses in wind energy at the faculty of engineering and technology of the university of Buea Cameroon as a visiting lecturer, He studied Geology and environmental sciences and Environmental Engineering at the University of Buea Cameroon and the Brandenburg Technical university Cottbus Germany respectively. Passionate about energy, his move towards renewable energy and energy generation has been a natural fit. In his free time he loves computer programming, swimming, bicycle riding, playing table, soccer, acting and board games such as chess and scrabble.

Abstract:

As of October 2014, 258.9 million hectares of agricultural land was being used for oilseed production. 5.5%, approximately 14.2 million hectares constituted land used for palm oil cultivation. With an estimated annual global production of 58.72 million tons in 2016, Palm oil has become the most important vegetable oil globally, greatly exceeding soybean, rapeseed and sunflower. It is the most efficient oilseed crop in the world, capable of producing up to ten times more oil than other leading oilseed crops per hectare. Annually, a hectare of mature palms could produce between 18 to 30 metric tons of fresh fruit bunches (FFB), 70-75% of which ends up as by-products or waste. Main by-products from the palm oil industry that could be used for their energetic values include the Palm Kernel shells, Empty fruit bunches, Palm oil Fiber, Oil palm trunks, Oil palm fronds and the Palm oil Mill Effluent (POME). On average a hectare of palm oil produces 15.8 tons of Palm kernel shells, empty fruit bunches, Palm oil Fibers and Oil palm fronds annually. Whereas at the end of it’s economic life span a hectare of palm oil is capable of producing an estimated 82.32 tons of dry biomass including Oil palm trunks. Residues from the palm oil plantation have a net calorific value in the range of 15MJ/kg to 22MJ/kg, comparable to brown coal (Lignite) and bituminous coal with net heating values in the ranges of 10-19MJ/kg and 15-24MJ/kg respectively. Greenhouse gas emission estimates from the production of 1kg of palm oil ranges from 0.02 to 8.32kg CO2 equivalent, with land use change and fertilizer input being the most contributors to its emission potential. The open incineration of most of these residues as a waste management process not only leads to an increase in the emissions from the sector, but also the energy from these residues is lost. Unfortunately, bioenergy still constitutes as low as 10% (50EJ) of the total primary energy supply as of 2017. With the main challenges facing the development of bioenergy being low oil prices, food security and policy uncertainty, second-generation biomass is undoubtedly the silver bullet solution to accelerate bioenergy access to the total energy mix in the near future.

Recent Publications:

- Bobbo Nfor Tansi (2012) An Assessment of Cameroons Wind and Solar Energy Potential: A Guide for a Sustainable Economic Development. Diplomica Verlag. 120p