Raphael Lechner

Technical University Amberg-Weiden, Germany

Title: Hydraulic Injection Characteristics of different Biofuels

Biography

Biography: Raphael Lechner

Abstract

As a part of a joint research project of the Centre of Excellence for combined Heat and Power and Fraunhofer UMSICHT, the hydraulic injection characteristics of various biofuels for diesel engine operation were investigated.

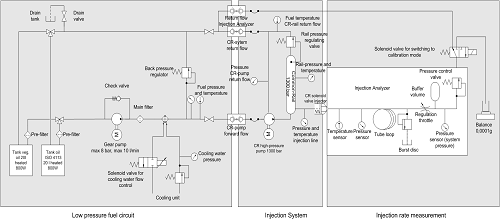

The measurements were carried out using a standard configuration common-rail injection system with a high pressure pump feeding into a common rail and a solenoid injector. The system was mounted on an injection system test bench, which was developed at the Technical University of Applied Sciences Amberg-Weiden (c.f. figure). The test bench features an IAV injection analyzer, which allows direct shot-to-shot measurement of injection rate and injection quantity for multiple injections per cycle, e.g. pre, main and post injection (c.f. [1],[2]).

The different biofuels investigated were pure rape seed oil, biodiesel, and crude bio-oil obtained from biogas digestate via Thermo-Catalytic Reforming (TCR®), a process developed at Fraunhofer UMSICHT (c.f. [3],[4],[5],[6]). Calibration fluid according to ISO 4113 was used as reference fuel.

The measurements were carried out at different rail pressures and injection durations in order to obtain the injector map for the different fuels. Additionally, measurements with different pre and post injection timings were performed to determine the closest possible timing of multiple injections according to the main injection.

The resulting injector maps clearly show the pressure dependency of injection quantities. Fuels with higher viscosity generally show considerable deviations from the reference fuel at lower injection pressures, whereas the differences diminish at higher injection pressures. Analysis of multiple injections shows that there is a minimum required lag time between the injection pulses to avoid converging of the individual injections. This lag time is generally higher when using fuels with higher viscosity.

Both phenomena indicate the need for recalibrating injector mappings and timings for engine operation when utilizing biofuels with fluid characteristics deviating from the reference fuel.

Recent Publications:

- Brautsch, M.; Lechner, R.: Common-Rail-Einspritzsysteme für Pflanzenöl-BHKW, University of Applied Sciences Amberg-Weiden Research Report 2008/2009, December 2008.

- Muntean, A.B. et.al.: Impact of different in-cylinder pressures on hydraulical performances of the diesel fuel injection systems, 15th International Conference on Experimental Mechanics, Porto 22-27 July 2012.

- Neumann, J. et.al.: Upgraded biofuel from residue biomass by Thermo-Catalytic Reforming and hydrodeoxygenation. Biomass and Bioenergy 89 (2016), p. 91-97.

- Neumann, J. et.al.: Production and characterization of a new quality pyrolysis oil, char and syngas from digestate – Introducing the thermo-catalytic reforming process. Journal of Analytical and Applied Pyrolysis 113 (2015), p. 137-142.

- Neumann, J. et.al.: The conversion of anaerobic digestion waste into biofuels via a novel Thermo-Catalytic Reforming process. Waste Management 47 (2016), p. 141-148.

- Conti, R. et.al.: Thermocatalytic Reforming of Biomass Waste Streams. Energy Technology 5 (2017), p. 104-110

Speaker Presentations

Speaker PPTs Click Here